Production of Ce-W-Ti Catalyst Using APT with Enhanced NH3-SCR Performance

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 April 2021 20:18

Nitrogen Oxides are a family of poisonous, highly reactive gases. These gases form when fuel is burned at high temperatures. It is major source is from vehicles, trucks, industry facilities and so on.

Presently, one of the commonly used technologies for controlling NOx emissions is selective catalytic reduction of NO with NH3 (NH3-SCR) using commercial V2O5/WO3(MoO3)/TiO2 catalysts. Although such catalysts exhibited good activity at 300–420 °C, vanadium-based catalysts are still not satisfactory due to the narrow working.

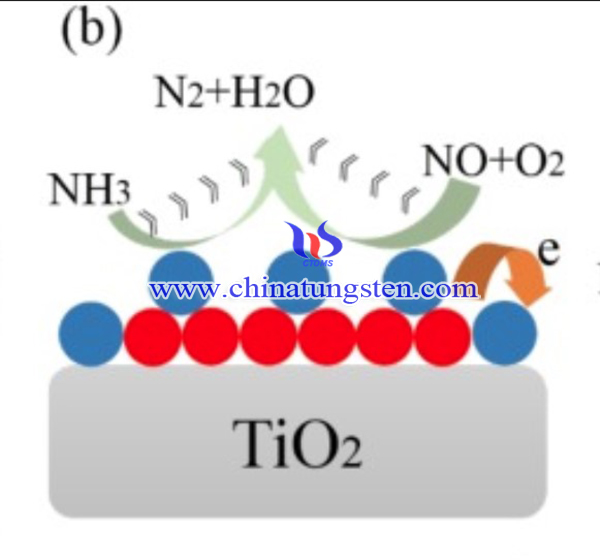

Tungsten trioxide (WO3) can significantly improve acidic and redox of CeO2/TiO2 catalyst, thus enhance their NH3-SCR performance. Therefore, a CeO2-WO2-TiO2 (Ce-W-Ti) catalyst with enhanced NH3-SCR performance had been produced with ammonium paratungstate (APT) as raw material.

The synthesis procedure of Ce-W-Ti catalyst was performed is as below:

The precursor of CeO2 and WO3 were the most common cerium nitrate (Ce3+) and ammonium paratungstate (W6+). The calculated amount of Cerium nitrate (Ce(NO3)3·6H2O), ammonium paratungstate ((NH4)6W7O24·6H2O) and TiO2 support (10–25 nm) were mixed in distilled water. Subsequently, the mixture solution was stirred at 80 °C for 2 h. After that, the obtained solution was dried at 120 °C for 5 h and calcined at 500 °C for 2 h in air.

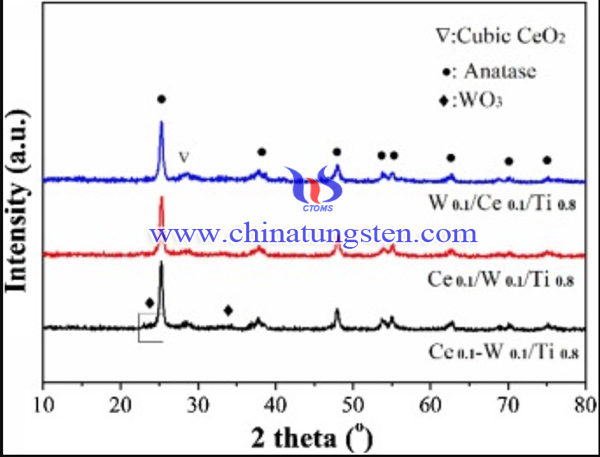

In the text, the different content of CeO2 and WO3 in Ce-W-Ti catalysts was abbreviated as CexWyTiz (x, y and z represented the weight content of CeO2, WO3 and TiO2). Eventually a Ce0.1W0.1Ti0.8 catalyst with enhanced NH3-SCR performance for NOx controlling has been synthesized.

In summary, the catalyst showed a wide active temperature window from 240 to 450 °C and the conversion of NOx was higher than 85%. Obviously, the loading sequence of CeO2 and WO3 and the loading ratio of CeO2/WO3 had a significant influence on the catalytic activity of Ce-W-Ti catalysts. Apparently, Ce-W-Ti catalyst displayed the highest activity below 240 °C. Based on the above results and discussions, active sites assembly effect would affect the acidity and redox properties of Ce0.1W0.1Ti0.8 catalysts. Combined with the analysis of the reaction process, it was concluded that the control step of NH3-SCR reaction at low temperature for Ce0.1W0.1Ti0.8 catalysts was the adsorption and activation of NH3.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com