WO3/MWCNT Nano Composite by Acid Precipitation via Ammonium Paratungstate for Gas Sensing Application

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2021 18:15

Nanostructured materials are of interest for many researchers as one of promising building blocks for many applications, such as gas sensing, photovoltaic cell and catalysis because of their large surface-to-volume ratio and the nanosize effect. Recently, there is increasing number of research teams exploring various means for synthesis and application of many nanostructured materials, such as titanium dioxide (TiO2), zinc oxide (ZnO), tungsten oxide (WO3), carbon nanotubes (CNTs), graphene, and so on.

A feasible preparation method WO3/MWCNT nano composite by acid precipitation via ammonium paratungstate (APT) had been conducted for gas sensing application.

The synthesis procedure of WO3/MWCNT nanosized composite is as follows:

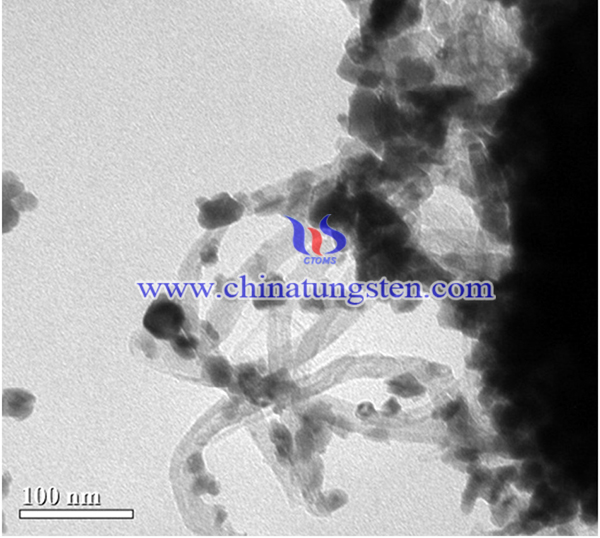

Ammonium paratungstate (APT), nitric acid (HNO3), and Multi-walled carbon nanotubes (MWCNTs, Baytubes®) were used as precursor materials. The inner and outer diameters of MWCNTs were 4 and 13 nm, respectively.

Firstly, 300 mL of APT and 0.045 g MWCNTs was heated in a flask at 80 °C. Then 50 mL of 4.5 M of nitric acid was added dropwise to accommodate hydrolysis reaction of tungstate salt. The mixed solution was kept under stirring and refluxing condition for 30 min to ensure the completion of hydrolysis. Then the solution was cooled to room temperature naturally and kept quiescently for one day. The prepared product was washed with de-ionized water and filtrated through nylon membrane with diameter of 0.45 μm until pH of the washed effluent equal to 7 and dried in oven at 100 °C overnight. The as-prepared particulate product was calcined under air atmosphere with various target temperature of 300–600 °C with a holding time of 1–5 h. Finally, the WO3/MWCNT nano materials was produced was filtrated and dried in a hot-air oven before calcined at a designated temperature of 400 °C for 3 h to prevent losing of MWCNTs from combustion.

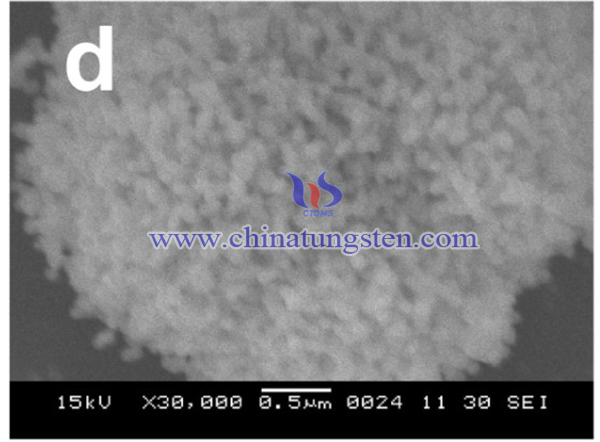

The synthesized WO3 nanoparticles and WO3/MWCNT hybrid materials were analyzed by scanning electron microscope (SEM), transmission electron microscope (TEM) to demonstrate morphology. Crystal structure was studied using an X-ray diffraction technique.

In conclusion, WO3/MWCNT nano composite materials has been produced using APT and MWCNTs. The optimal calcination temperature which could provide WO3/MWCNT hybrid material with uniform dispersion of WO3 on the MWCNT surface would be 400 °C. Regarding to the mesoporosity and the BET surface area of 15.6 m2/g with average pore size of 9.2 nm, the fabricated WO3/MWCNT hybrid material would exhibit potential for gas sensing applications.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com