Ammonium Paratungstate Used in Photocatalytic WO3-Tio2 Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 December 2020 01:06

Employing semiconductor powders as photocatalysis for the degradation of organic pollutants in water has received a lot attention in the last decade. Titanium dioxide (TiO2) inhibits amazing photocatalyst properties including high activity, chemical stability, and low cost. Nevertheless, the photocatalytic activity of TiO2 (with band gap of 3.2 eV and excited by photons with wavelengths under 387 nm) is still limited to irradiation by UV wavelengths, so that photocatalytic process does not occur effectively during the irradiation with solar light as only about 4% of the total radiation of the solar spectrum is in ultraviolet region.

Thus, modification of TiO2 in the view to obtain a higher light absorption by shifting absorbance to the visible wavelengths has become the aim of many authors. One of the methods is the coupling of TiO2 with other semiconductors such as TiO2/CdS, TiO2/SnO2, TiO2/ZnO, and TiO2/WO3.Three different procedures were followed to prepare coupled catalysts that offer a higher photocatalytic performance than unloaded TiO2 tageting the oxidation of salicylic acid (SA) in aqueous solution.The synthesis procedures are as follows:

TiO2 (P25), titanium tetrachloride (TiCl4, 98%), tungstic acid (H2WO4, 99%) and ammonium paratungstate (APT, >99%) were used as purchased without further purification. The pollutant model was the salicylic acid (SA) (C7H6O3, ≥98%).

All the coupled titania samples were deposited on a substrate which consisted in a flat plate of ordinary glass 4 cm × 48 cm. The substrate was pre-treated with dilute nitric acid and washed with NaOH solution in order to increase the density of OH groups on the surface of the glass which enhances the binding of TiO2, then rinsed by distilled water and finally dried. Coupling TiO2 by WO3 and deposition were carried out according three different procedures:

Procedure 1: this is the incipient wetness method of Lin and Kwon et al. [8], [13], it consists briefly on the following steps: TiO2-powder (P25 Degussa, 4 g L−1) was suspended under vigorous stirring in a dilute ammonia solution, which was allowed to dissolved with a stoichiometric amount of tungstic acid (H2WO4), the suspension was then deposited on the glass substrate, dried in the air and fired at 450 °C during 4 h. The same deposition procedure was repeated three times so as to obtain a thick layer with deposed specific mass of about 0.2 mg cm−2 (±0.05 mg cm−2), above this value it was demonstrated that the rate of photocatalytic degradation of SA with TiO2-P25 deposit was constant.

Procedures 2 and 3: these two procedures consisted in spin coating deposition of the catalysts on the same glass substrate by a spin coater machine, a speed set to 1500 rotations per minute. A viscous form was needed in order to use this deposition method; for this reason a powder of TiO2-P25 with APT was mixed with a monomer (C12H10O4 called HDDA) in the second procedure, and a viscous gel of WO3/TiO2 was prepared via sol–gel method in the third procedure according the following step: a 0.05 mol TiCl4 was dissolved in 100 ml absolute ethanol under vigorous stirring, then diluted by 150 ml of water. The ammonium paratungstate powder was introduced at this step according to the choosing molar ratio. Afterwards, the ammonia solution was dropped into the TiCl4/ethanol/water/APT solution and the titanic acid gel precipitated. The gel was rinsed and separated by centrifugation until the Cl− ions could not be detected. Then a H2O2 solution (30 wt.%) was added drop-wise to the gel under vigorous stirring until a yellow and viscous solution was obtained, which was suitable for spin coating deposition. Only one deposition was done with spin coating method and deposed specific mass was about 0.07 mg cm−2 (±0.02 mg cm−2) and 0.2 mg cm−2 (±0.05 mg cm−2) respectively for films prepared by the second and the third procedure. All catalyst deposits were dried and fired in air at 450 °C during 4 h, annealing temperatures in the same range (400–500 °C) were used for the preparation of coupled WO3/TiO2 catalysts.

2.2. Analysis

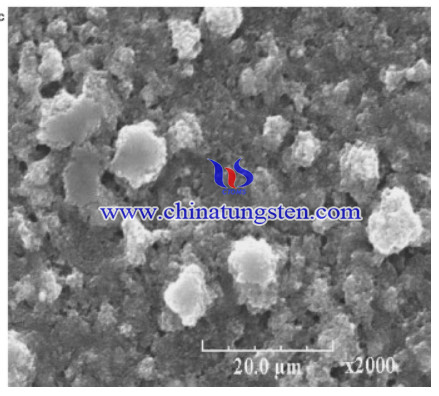

The absorption of catalysts over the entire spectrum (200–700 nm) was monitored in a UV-Vis spectrophotometer equipped with an integrating sphere (diameter: 150 mm, type: LISR-2100). The structure of catalysts was characterized by X-ray diffraction technique (XRD) using the “Panalytical” instrument (X’Pert Pro MPD). The SEM diagrams were obtained from Jeol T330 equipped with a XRD Synergy system. Salicylic acid concentration was monitored by HPLC on a chromatograph equipped with a Shimadzu SPD-6A spectrophotometric detector adjusted to the wavelength of 295 nm, corresponding to the maximal absorption of SA. A Lichrosob column was used and elution was carried out by a mixture of methanol (70%) and water (30%).

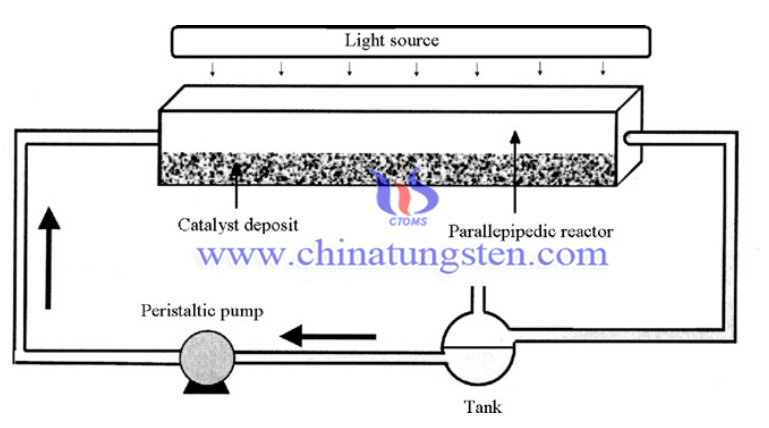

2.4. Photocatalytic tests

The photocatalytic reactor (See image) consisted in a parallepiped vessel with the catalyst fixed on a flat glass Plate 4 cm × 48 cm placed on the bottom, as detailed elsewhere. Photocatalytic activities of prepared samples were tested for decomposition of 250 ml salicylic acid (SA) aqueous solution running freely on the plate with a debit of 220 ml min−1. The initial concentration of SA was fixed to 10 mg L−1 (arbitrary value) and monitored by HPLC chromatography. Two different light sources were used for photocatalytic tests: UV and white lamps. The UV lamp (Philips-TLD, 18 W, 56 cm long) emits in the range of 350-390 nm with a maximum at around 365 nm having an intensity of 2.83 W m−2. The white lamp (Osram-L, 18 W, 56 cm long) provides mainly visible light in the range of 400–600 nm and insignificant amount of UV at 365 nm (0.13 W m−2).

In conclusion, doping of WO3 to TiO2 has seen a great improvement on his photocatalytic properties: the coverage on the glass was improved, the band gap energy decreased to 2.3 eV with 4 wt.% of WO3 and the corresponding photocatalytic activity was remarkably enhanced under visible light. A higher photocatalytic activity and a better response to WO3 introduction was also observed under UV irradiation. The introduction of tungsten precursor before the crystallization of TiO2 seems to be an appropriate method to ensure good contact and better charge transfer between the two semiconductors. As expected, the photocatalytic performances were generally higher under UV light than under visible light for all the catalysts and 0.5 wt.% WO3–TiO2 was the common optimal loading for the 3 procedures exhibiting the best activity under UV light.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com