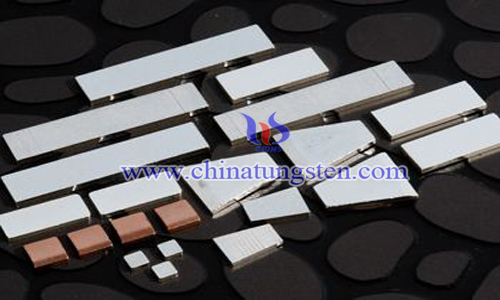

Flake Silver-Tungsten Electric Contact Material Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2019 23:24

Silver-tungsten electrical contacts are widely used in various household appliances due to their good thermal conductivity, electrical wear resistance, welding resistance and oxidation resistance.

Researchers have proposed a preparation method of sheet silver-tungsten electrical contact material, which includes the following steps:

1)Calculate the amount of tungsten trioxide powder and silver nitrate needed according to the material proportion of the silver-tungsten electrical contacts to be prepared, and calculate the amount of sodium hydroxide needed for the reaction of silver nitrate and sodium hydroxide to produce silver oxide according to the amount of silver nitrate, which is called standby; dissolve silver nitrate with water and prepare 20-40w/w% silver nitrate solution, and place the tungsten trioxide powder and silver nitrate solution in the reaction. In the device, the suspension containing silver nitrate and tungsten trioxide is obtained by stirring evenly.

2)Sodium hydroxide was prepared into 10-30w/w% sodium hydroxide solution and added into the suspension obtained in step 1. The suspension was stirred and precipitated, filtered, and the composite powder of silver oxide and tungsten trioxide was obtained.

3)The silver oxide and tungsten trioxide composite powders were washed to neutral, dried and crushed, then roasted, and then crushed to obtain silver tungsten oxide composite powders.

4)Silver tungsten oxide ingot was obtained by isostatic pressing and sintering in oxygen atmosphere.

5)The obtained silver tungsten oxide billet was hot extruded and machined to obtain sheet silver tungsten oxide contact material.

6)The silver-tungsten oxide contact material is reduced in a reducing atmosphere and then repressed in an oil press to obtain the silver-tungsten oxide contact material.

The composite powder of silver oxide and tungsten trioxide was obtained by the reaction of sodium hydroxide with silver nitrate suspension containing tungsten trioxide powder, which improved the agglomeration phenomenon of tungsten powder caused by uneven stirring between tungsten powder and formed silver powder due to excessive density difference in existing technology, and made the distribution of tungsten trioxide in silver tungsten oxide composite powder obtained by reaction more dispersive and uniform, and omitted. The high energy ball milling process in the prior art makes the preparation process simpler.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com