Mesoporous Cerium Oxide Material Containing Highly Dispersed Tungsten

- Details

- Category: Tungsten Information

- Published on Friday, 30 August 2019 22:17

In recent years, due to the rapid development of automotive industry, the demand for fuel oil is increasing all over the world. The exhaust gas from sulfide combustion in fuel has brought serious environmental problems, so it is particularly important to limit the sulfur content of fuel. Oxygen desulfurization technology has high desulfurization efficiency and mild reaction conditions. Under ambient temperature and pressure conditions, low operating cost and simple process have attracted much attention.

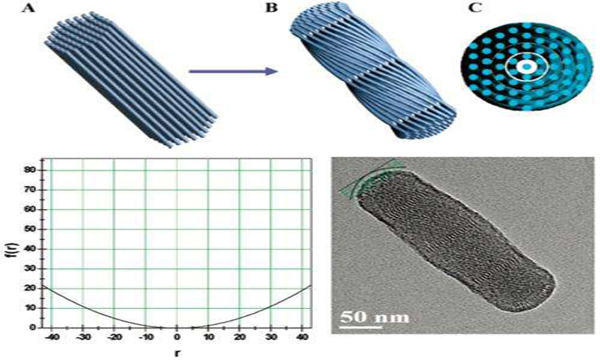

Mesoporous materials have large specific surface area, adjustable pore size and pore type, allowing larger molecules to participate in the reaction and other characteristics. They are a good catalyst carrier. In this material structure, catalytic active centers are introduced to develop supported mesoporous materials catalysts. For example, a mesoporous cerium oxide material containing highly dispersive tungsten can be prepared by dissolving the model agent in water, dissolving the tungsten-containing ionic liquid in acetonitrile, then adding cerium source and ammonia water to react, then transferring it into the reactor, filtering and precipitating, washing it to neutral, drying, and finally heating and calcining it with a program. A mesoporous ceria material containing highly dispersed tungsten is obtained. The concrete steps are as follows:

1)Dissolve the imidazole model agent in a certain amount of water, dissolve the tungsten-containing ionic liquid with acetonitrile, then add the acetonitrile solution drop by drop into the water solution of the imidazole model agent, stir evenly, and get the mixed solution.

2)Adding cerium source and ammonia water to the mixed solution obtained in step (1), stirring reaction, moving to high-pressure reactor, filtering and precipitating after reaction, washing the precipitated water to neutral, drying and grinding, and heating the grinded powder to 300-600 ℃ in the programmed heating tube furnace for 3-6 hours, resulting in high dispersion mesoporous cerium dioxide materials.

Mesoporous cerium oxide materials containing highly dispersed tungsten have mesoporous structure, uniform pore size distribution and large specific surface area. These characteristics ensure that the active sites of catalysts are uniformly and highly dispersed, and that the sulfur-containing substrates are fully contacted with the active sites and have high activity.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com