Large Area Monolayer Tungsten Disulfide and Molybdenum Disulfide Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 11 August 2019 12:40

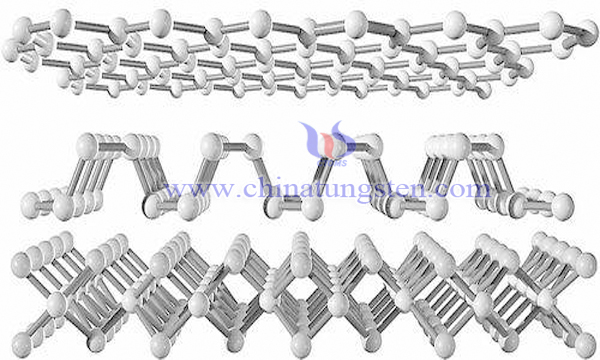

As a high-tech industry in the 21st century, the rapid development of semiconductor industry has far exceeded the traditional iron and steel industry and automobile industry. Silicon material is the cornerstone of semiconductor industry, but with the increasing integration, the shrinkage of size will mainly lead to leakage and static power density of devices. Recently, transition metal chalcogenides, especially tungsten disulfide and molybdenum disulfide, have attracted much attention in the scientific community due to their excellent electrical, optical and mechanical properties, as well as graphene, as a potential post-silica material.

In order to prepare large area monolayer tungsten disulfide and molybdenum disulfide structures, a step-by-step gas phase method has been used by some researchers. The method can prepare uniform monolayer tungsten disulfide and molybdenum disulfide on a 100 square centimeter substrate. The operation contents are as follows:

First, chemical vapor deposition, sputtering or thermal evaporation were used to deposit 2-50 nanometer tungsten or molybdenum oxide films or molybdenum-tungsten mixed oxide films on silicon, silicon dioxide, silicon carbide, aluminium oxide or titanium dioxide substrates ranging in size from 1 square centimeter to 100 square centimeter. Deposition time ranges from 10 minutes to 24 hours at 100 to 500 degrees Celsius. Substrates deposited with oxide films react with elemental sulfur in inert gas or hydrogen atmosphere at high temperature from 550 to 1100 degrees Celsius, reaction pressure from 1 millibar to 1 bar, reaction time from 30 seconds to 10 minutes, and large area of monomer is obtained after natural cooling. After natural cooling, a large area of tungsten disulfide or molybdenum disulfide monolayer was obtained.

Stepwise vapor phase method was used to prepare monolayer tungsten disulfide and molybdenum disulfide on 100 square centimeter substrates with simple reaction and good controllability.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com