Rapid Sintering Technology of Tungsten Carbide-based Cemented Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 29 July 2019 22:01

Cemented carbide is a kind of alloy material which is made by powder metallurgy process, with high hardness and refractory metal carbide powder (WC, TiC, TaC, NbC, etc.) as the main phase and transition metal cobalt, nickel as the binder phase. With high hardness, high strength, high toughness, wear resistance, high temperature resistance and small expansion coefficient, it is widely used in cutting, drilling, mining, tool forming and wear-resistant parts and other fields.

In order to achieve the balance of performance and cost, the researchers adopted the following rapid sintering technology scheme:

Tungsten carbide-based cemented carbide is made of composite raw materials, which include at least five components of molybdenum powder, vanadium carbide, chromium carbide, titanium carbide, silicon carbide and yttrium oxide, and the binder is cobalt powder.

1.Grinding: Each component is weighed separately and mixed together to obtain composite material; paraffin is added to the composite material, and then the composite material is ground at 50-70 ~℃ for 36-72 hours, followed by vacuum drying for 1-2 hours.

2.Screening: Compound materials can be screened by sieving of more than or equal to 100 meshes.

3.Pre-sintering: The sifted mixture is made into green body, then the green body is heated to 600-800 degrees Celsius gradually, then the green body is kept for 70-90 minutes, and then cooled to room temperature.

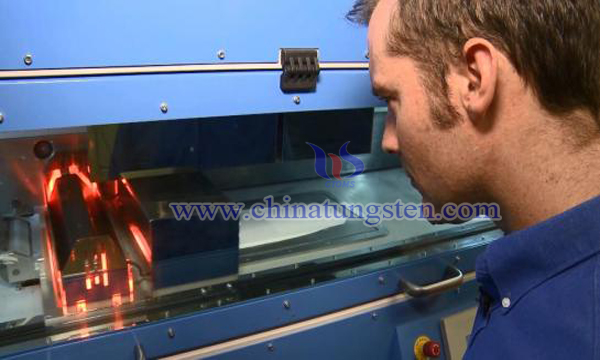

Sintering: Under the protection of nitrogen and/or inert gases or vacuum conditions, the green body is gradually heated to 1350-1430 ℃, then kept for 50-70 minutes, and then cooled to room temperature. The vacuum degree of the vacuum condition is 0.1-10 Pa.

The process includes adding at least five kinds of molybdenum powder, vanadium carbide, chromium carbide, titanium carbide, tantalum carbide, and lanthanum oxide to form a gain agent in a certain ratio, thereby suppressing excessive or irregular growth of the tungsten carbide grains, and making the tungsten carbide base hard. The alloy has higher strength, toughness and plasticity; especially when used in the best proportion, the tungsten carbide-based cemented carbide can have better comprehensive mechanical properties, better effect, high hardness and high toughness, hardness of 15 -25GPa, the fracture toughness is 4-8MPa•m1/2, which can also reduce the grinding time of materials, shorten the production cycle and reduce the production cost.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com