Tungsten-based Alloys with High Specific Weight Preparation by Plastic Matrix System Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 July 2019 22:54

High specific gravity tungsten-based alloys are mainly composed of nickel, iron, cobalt, copper, chromium and other elements. The existing methods of preparing tungsten-based alloy materials are usually powder injection moulding, mainly using wax matrix system to make powder injection moulding.

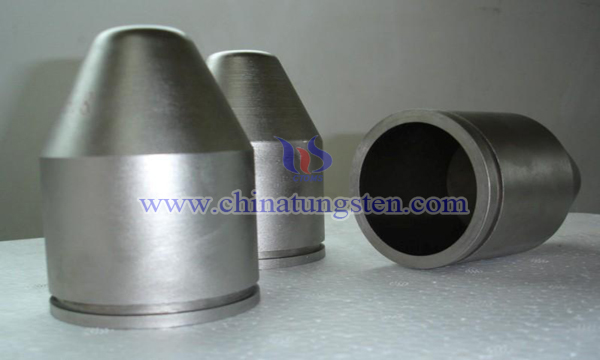

High specific gravity tungsten-based alloys are mainly composed of nickel, iron, cobalt, copper, chromium and other elements. The existing methods of preparing tungsten-based alloy materials are usually powder injection moulding, mainly using wax matrix system to make powder injection moulding. In order to avoid the influence of surface oxidation on sintering, molybdenum sintering furnace is usually used to sinter with hydrogen. The equipment cost is high and the maintenance cost is high. When the specific gravity of W-Ni-Fe alloy is 10-16g/cm3, the content of Ni-Fe is high, and the mechanical properties of sintered products are low. So how can the plastic matrix system process be used to prepare tungsten-based alloys with high specific gravity? Researchers have proposed such a scheme:

(1)Ingredients: Tungsten, nickel and iron powders are mixed according to a certain weight ratio to obtain mixture A.

(2)Dry grinding: mix A dry grinding, mixing evenly;

(3)Mixing and granulation: Mixture A treated by steps (2) is stirred under nitrogen protection and at a speed of 10-15 rpm/min, and preheated for 20-25 min at 200-210 ℃; then heated and added with plastic accessories and polyformaldehyde resin (POM), then heated to 230-240 ℃, kept for 5-10 min, POM melted and then put down the laminated cover. Internal mixing, while starting to cool down, after cooling to 200-210 ℃, continue to mix for 10-15 minutes until the surface of the material is uniform and smooth, then cooling to 180-190 ℃, and then extruded by screw and cut into granules.

(4)Injection Molding: Material is extruded through the die cavity;

(5)Degreasing; catalytic degreasing with nitric acid.

(6)Sintering: vacuum sintering in graphite furnace or molybdenum furnace.

In Tungsten-Nickel-Iron alloys, the sintering temperature of tungsten is high, so it is difficult to sinter directly. Nickel and iron are the bonding phases. When sintering, the tungsten particles are bonded together to form alloys by melting nickel and iron. Iron can reduce the solubility of tungsten in nickel, effectively prevent the formation of beta brittle phase, thereby improving the strength and toughness of tungsten alloys. In summary, using the process of plastic matrix system to produce tungsten-based products with high specific gravity has better stability, less deformation, shorter manufacturing cycle and higher efficiency.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com