Tungsten Alloy Counterweight Rod in Stone Crusher

- Details

- Category: Tungsten Information

- Published on Friday, 19 July 2019 14:39

A stone crusher comprising a tungsten alloy counterweight rod provides an opportunity to change the weight and counterweight to optimize mass action in stone crusher.

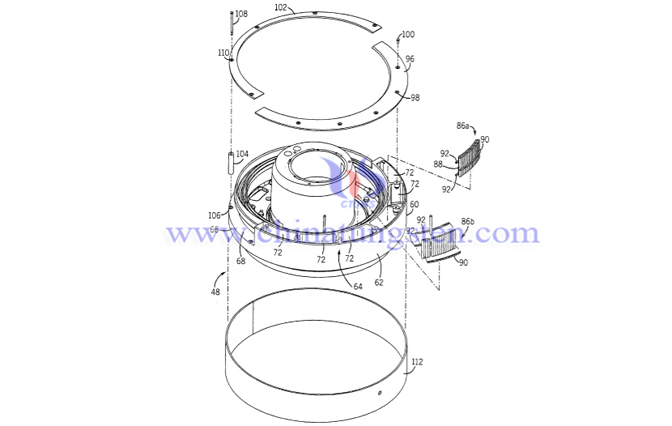

Figure 3 shows an embodiment in which one or more separate compartments 72 places the first ballast 86. Figure 3 shows two separate first ballast 86a and 86b, although a different number may be used first ballast, such as one or three. In this embodiment, ballast 86 includes a first group of individual goods 88 arranged form a first ballast. The individual loads 88 are made of a material different from the material of the counterweight main body, for example of tungsten alloy counterweight rod, connected to each other by an external connector 90 and a pair of inner connectors 92. It is assumed that the goods may have shapes other than rods or may be solid block or plate, while works within the scope of the present disclosure in stone crusher.

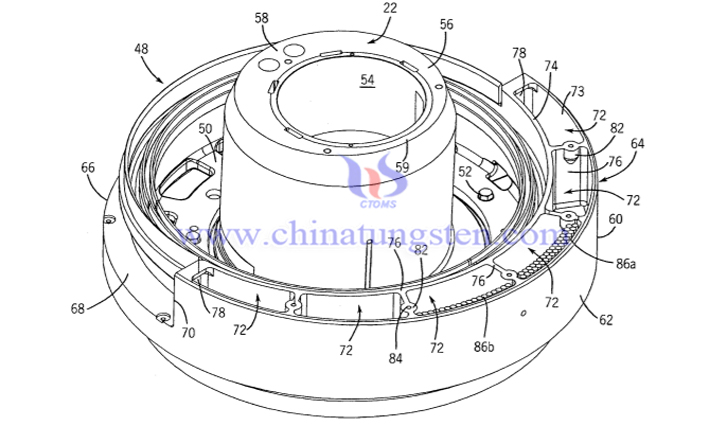

In the illustrated embodiment in Figure 3, the first ballast 86a includes two rows of tungsten rods, while the first ballast 86b includes only one series of tungsten rods. As will be described in detail below, the number of individual loads 88 located in each of the compartments 72 may be selected during design of the counterweight assembly 48. In the embodiment shown in Figure 2, only two compartments 72 include a first ballast 86. However, it is contemplated that any number of five compartments 72 may include a first ballast 86 depending on the particular design of the counterweight assembly.

During the creation of a counterweight assembly 48, individual compartments 72 are filled with a first ballast 86, as required. As described, in the embodiment shown in Figures 2 and 3, only two of the five compartments 72 include a first ballast 86. In the illustrated embodiment, the first ballast is made from a very dense material such as tungsten alloy rods. However, it should be understood that the first ballast 86 may be made of other materials, and separate loads 88 may have other shapes rather than tungsten rods, shown in Figure 3.

As shown in FIG. 5, after the positioning of ballast 86 in the first compartment, 72 of the second ballast 94 can be placed in the compartment 72 to further increase the weight assembly 48 of the counterweight. In this second embodiment, the ballast 94 is made of a second material different from both the first material and the base material used to form the body of the counterweight. In the illustrated embodiment, the second material is a lead which is poured into the open compartment 72, and surrounds the first ballast 86. Although in this embodiment, lead is used, other materials may be used as the second ballast 94.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com