Adipic Acid Synthesis with Nano Tungsten Trioxide Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 23:10

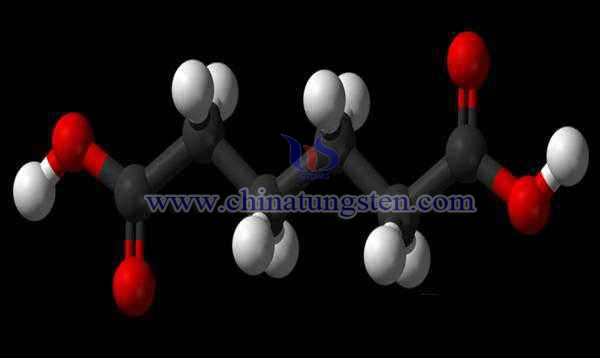

Adipic acid is an important organic dibasic acid, which is mainly used in synthetic fibers, namely nylon-66. The annual consumption of adipic acid is very large. At present, the traditional production process of adipic acid synthesis is still widely used in industry, that is, using concentrated HNO3 as oxidant. This process is very harmful to the environment.

In order to solve the above problems, a rod-like nano tungsten trioxide catalyst for synthesis of adipic acid was prepared by following technical schemes:

Accurately weigh 6.6g Na2WO4·2H2O·(0.02mol) into 50mL water, and add HCl (9mL) with a measurement ratio of 1:1 drop by drop under the condition of magnetic stirring. After stirring, 5.48g (0.04mol) p-aminobenzoic acid was added and stirred for 0.5H. The mixture was poured into the reactor. The reaction time was 24 hours in an air blast drying chamber at 180 ℃. The obtained material was washed repeatedly with ethanol and water, filtered and dried to obtain rod-like nano tungsten trioxide catalyst.

0.0356g catalyst, 0.1g oxalic acid, 4.1ml 30% H2O2 and 8mmol cyclohexene were added to 10mL reaction vessel. The reactor was placed in oven at 90 ℃ for 12 hours. After reaction, acetone was added to a certain amount of acetone. The catalyst was separated by centrifugation, and the supernatant was steam-evaporated and air-dried to obtain adipic acid.

The results show that the rod-like nano tungsten trioxide catalyst has high catalytic activity for adipic acid synthesis with fewer additions, and can catalyze cyclohexene to adipic acid cleanly and efficiently without organic solvent and phase transfer agent.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com