Nano Single Layer Tungsten Disulfide Reinforced Carbon Fiber Sizing Agent

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 15:41

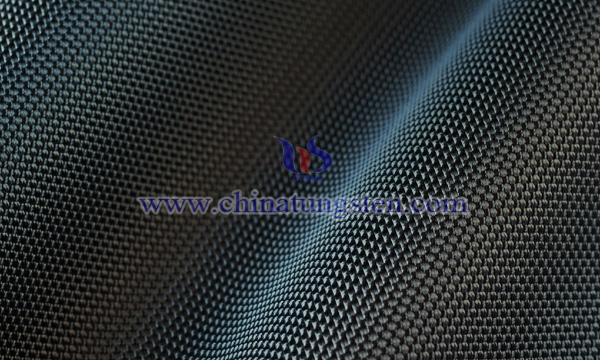

Carbon fiber is known as a new inorganic material. It has a series of excellent properties such as high specific strength, high specific modulus, high temperature resistance, corrosion resistance, fatigue resistance, radiation resistance, conductivity, heat transfer, shock absorption and noise reduction. As a typical high performance fiber, carbon fiber is widely used as a reinforcing fiber of advanced resin matrix composites. At present, its application field is mainly in aviation and aerospace. It can greatly reduce the weight of prefabricated parts and further improve the technical performance.

In order to improve the shortcomings of domestic carbon fiber manufacturing technology, researchers used a new sizing agent nano single layer tungsten disulfide to improve this shortcoming. The preparation of sizing agent with nano tungsten disulfide can solve the problem of interface performance between carbon fibers and matrix. It has good stability and can effectively improve the processing performance of carbon fibers. The preparation method is simple and low cost. It can also be applied to different kinds of resin matrix by changing the composition of sizing agent. The preparation process of nano-single-layer tungsten disulfide reinforced carbon fiber sizing agent is as follows:

Step (1): Disperse the organic resin in the organic solvent at 35 - 100 ℃ to form the organic resin solution. The quality of the organic solvent is 20 - 200% of that of the organic resin.

Step (2): When the organic resin solution is reduced to room temperature, the emulsifier, dispersant and deionized water are mixed evenly and then added into the organic resin solution. The emulsifying agent added is the 1-5% of the organic resin. The dispersing agent added is the 0.1-1% of the organic resin, adding deionized water to the mixed system and the solid content of 30-50% is obtained, and the organic resin emulsion is obtained.

Step (3): The compatible modified nanosheet layer two tungsten sulfide dispersion was slowly added into the organic resin emulsion, dispersed by ultrasonic, and then added deionized water until the solid content of the system was 25-35%. The compatible modified nanosheet layer two tungsten sulfide reinforced sizing agent was prepared.

The prepared compatible modified nano-sheet tungsten disulfide can protect carbon fibers and improve the mechanical properties of the composites. This kind of functional sizing agent can optimize the interface and macroscopic properties of carbon fibers and their composites, which is of great significance to the upgrading of carbon fibre composites industry.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com