Hydrothermal Method to Prepare Tungsten-copper Composite Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 13:04

Tungsten-copper composite material is a pseudo-alloy composed of tungsten (high melting point, high hardness ) and copper (high conductivity and thermal conductivity). It is an excellent material to be applied in electrical contacts and electrodes. The combination of low-expansion-coefficient tungsten and high-conductivity copper can be applied to heat sink substrates of airtight packaging such as CPU, IC, solid state microwave tube, radio communication device. It is also used in ultra high voltage electrical contact materials and nozzles. Throat liner, electron beam target and plasma-oriented divertor material.

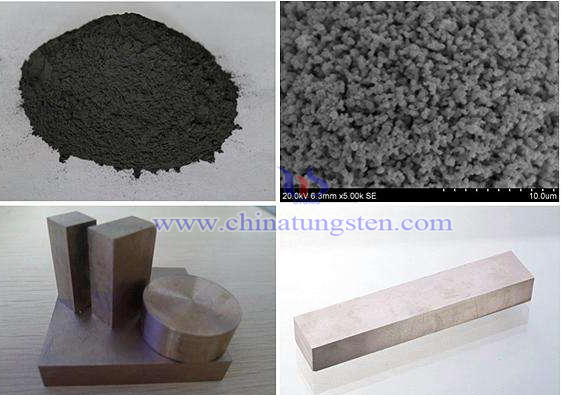

For the preparation of tungsten-copper composites, the density of tungsten-copper composites prepared by conventional infiltration and powder metallurgy methods is usually not higher than 98%, which is not suitable for the formation of high-performance tungsten-copper composites, and the emerging laser sintering The method and plasma sintering method are still in the experimental stage. The particle size and uniformity of the tungsten-copper composite powder largely affect the density of the tungsten-copper composite. Therefore, in order to obtain a dense tungsten-copper composite, it is necessary to use a tungsten-copper composite powder having fine particles and uniform mixing.

The preparation method of the conventional tungsten-copper composite powder has physical method and chemical method. Although the physical method is simple in operation, low in cost, easy to introduce impurities, low in purity, and uneven in particle distribution, the advantage of chemical synthesis lies in its adjustability and variety. Sexuality, the most striking feature is the uniformity that is unmatched by other methods.

Hydrothermal method is an important method for preparing nanomaterials. The process is not complicated. The prepared powder can completely control the grain size and morphology through temperature and time control. The particles have high purity and good dispersion. The crystal shape is good and controllable, and the production cost is low. The tungsten-copper composite powder with tungsten-coated copper phenomenon is prepared by hydrothermal method, and the process includes:

Step 1. Weigh the sodium sulphate dihydrate and the copper nitrate trihydrate according to the atomic concentration ratio of W and Cu, and prepare them into a solution with a concentration of 0.8 mol/L, respectively, to the obtained copper nitrate trihydrate solution. Add ammonia water and mix it thoroughly at 30 ° C to produce sufficient copper complex ions in the solution, then add the prepared sodium tungstate solution, then add nitric acid to adjust the pH of the mixed solution to 5.2-6.2. And fully stirred in a magnetic mixer for 2-5h, then set aside;

Step 2: The obtained mixed solution is charged into a stainless steel reaction vessel, and the mixed solution is charged in a volume of 80% of the stainless steel reaction vessel, and the reaction is carried out for 24 to 48 hours at a temperature of 150-180 ° C, and then cooled to room temperature in the furnace.

Step 3: The product obtained in the second step is filtered, and then ultrasonically washed with deionized water and absolute ethanol, and then freeze-dried to obtain CuWO4 nanoparticles for use.

Step 4: Put the CuWO4 nanoparticles into a hydrogen reduction furnace for phased reduction, the first stage: 320-380 ° C, heat preservation 08h-1.2h; the second stage: 750-800 ° C, holding time: 1h-1.5h, after Naturally cooled, the finished tungsten-clad copper-type tungsten-copper composite powder is obtained.

The preparation of CuWO4 nanoparticles by hydrothermal method is simple and easy to operate, reduces the calcination process in the prior method, has low energy consumption, and the recovery rate of copper ions in the whole preparation process can reach over 99%, which is much higher than that of the traditional method. 50%-65%.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com