Preparation Method of Tungsten Oxide Alloy Electrode with High Stability

- Details

- Category: Tungsten Information

- Published on Friday, 31 May 2019 13:47

With the development of science and technology, the preparation and processing methods of materials have made great progress. Arc plasma technology is a process that has been rapidly popularized in recent years. It is widely used in industrial fields such as plasma welding, cutting, spraying, melting and other materials preparation and processing, as well as emission electric light sources, microwave power tubes, vacuum tubes, and ion bodies. Fields such as propellers.

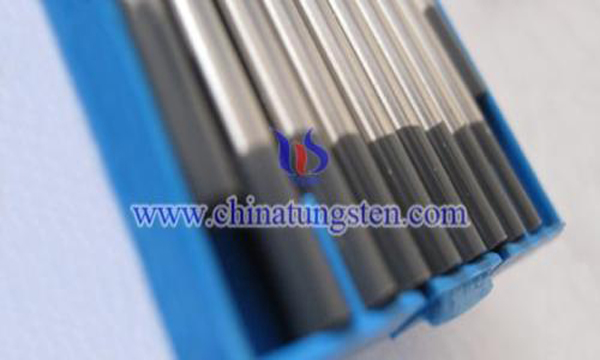

Tungsten electrodes are the most critical components in these devices and function as a current carrying and arc ablation, which plays a decisive role in the arcing characteristics of the arc plasma and the stability of the arc plasma. However, during the use of the tungsten electrode, due to the high temperature of the arc plasma and the presence of oxygen in the environment, the surface of the electrode is ablated, and tungsten and oxide on the surface of the electrode are subjected to different degrees of material loss, resulting in unstable performance ,and even the scrap of the electrode.

In order to overcome the problems of ablation and performance instability of tungsten oxide electrodes, material workers in various countries are working on new cathode materials. At present, plasma processing equipment in China mostly relies on imports from Japan, Europe or the United States, and electrodes are generated as plasma. The core components and consumables are also provided by the manufacturer of the equipment. Although China has a very rich tungsten resource and long-term development of tungsten oxide electrode materials, the current production of tungsten electrodes is difficult to meet the requirements of the use of foreign imported equipment.

The main reason is that the current method of tungsten oxide electrode in China adopts the method of reducing the addition of strontium oxide with tungsten oxide. The size of the oxide is large and the distribution is uneven, and this method has large energy consumption and serious pollution. The resulting electrode products have a low service life and arc instability during use, affecting the accuracy and quality of plasma processing. This is also the reason why domestic electrode manufacturing enterprises have no market, and the price of foreign electrodes is high. This is inconsistent with China's abundant tungsten resources and bulk tungsten exports.

In order to improve the current market conditions and improve the quality of domestic products, some scholars have published a tungsten oxide electrode material that can improve the stability of the arc, increase the surface tension of liquid tungsten on the surface of the electrode in the arc zone, and reduce the loss of tungsten. Its preparation process. The main principle of the preparation process is as follows: firstly adding a weight ratio of 0.1 to 1% of carbon and 1 to 5% of Nb, V, Zr, Cr, Al, Mo to form a alloying element in the tungsten powder. Or several kinds; then adding 0.5% to 4% by weight of bismuth, antimony, bismuth, antimony and other oxide powders with low work function; after cold pressing, sintering, and then by swaging, rolling, drawing, The polishing process achieves the desired electrode size. The specific operation is:

First, a weight ratio of 0.1% carbon (C), 5% niobium (Nb), and 0.5% ThO2 powder are added to the tungsten powder, and after mixing uniformly, the strip-shaped billet is cooled by cold pressing at 1500 K of hydrogen. Pre-sintering in the environment, followed by final sintering at 2800K, and finally through the process of swaging, rolling, drawing, polishing and other processes to achieve the desired electrode size.

The progress of the process is: a small amount of alloying elements are added to the tungsten powder, which can balance the decomposition process of the oxide added during the arcing process and control the decomposition rate of the oxide. These alloying elements solid solution with the tungsten phase or form a compound to stabilize the sintering and burning. The growth of tungsten grains during arc high temperature. During the arcing process, the oxygen inside the material and around the arc is absorbed to form a high melting point oxide, which reduces the loss of oxides in the electrode. At the same time, it participates in the combustion process of the arc, improves the stability of the arc, increases the surface tension of the liquid tungsten on the surface of the electrode in the arc zone, and reduces the loss of tungsten.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com