The Preparation Method of Urchin-Shaped Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 May 2019 13:36

With the increasing shortage of fossil fuels and the harsh environmental pollution, photocatalytic technology has received a great attention.It is applied in transformation of solar energy, degradation of organic pollutants. The advances in photocatalytic technology rely on the function of semiconductor materials.

Among the many photoanode materials, tungsten oxide is considered a promising candidate because it has a forbidden band width (2.5–2.8 eV) suitable for light absorption, a high electron mobility of 1.8e-3(m/s)/(V/m), and corrosion resistance acidic solution.Studies have shown that high oxygen defects, large specific surface area, exposed crystal face, composite semiconductor heterojunction can improve the photocatalytic performance of tungsten oxide materials.

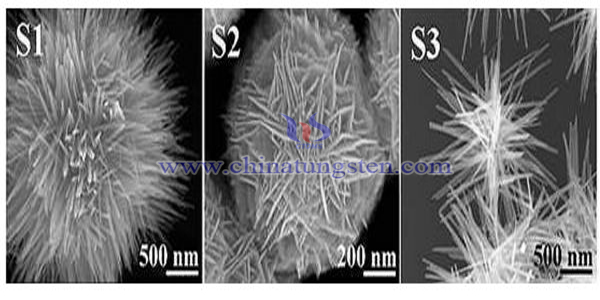

The morphology and morphology of tungsten oxide are nanorods, nanoflowers, nanospheres, nanowires, nanosheets, etc. Among them, flower-like and cluster-like structures have larger specific surface area, which is more conducive to increasing the adsorption of tungsten oxide on reactants. However, in order to obtain a controlled morphology during the preparation process, some surfactants are often used. These surfactants remain on the surface of the tungsten oxide, which may affect the performance of the tungsten oxide. The removal by the high temperature method is easy to destroy the nanometer. Structure, therefore, it is necessary for material workers to develop a more controllable, non-toxic, non-polluting, low-cost, and easily available tungsten oxide catalyst synthesis method. For example, a method for synthesizing urchin-shaped tungsten oxide, the specific steps are as follows:

Step 1, the particle size of 6-8μmW powder is added to the concentration of 30% H2O2, while adding a small amount of deionized water, 60-70 ° C water bath 30-40min until the W powder is completely dissolved;

Step 2, after the solution obtained in step 1 is allowed to stand for 24-72 hours, NaCl is added and stirred uniformly, and the amount of NaCl is controlled at a molar ratio of W to Cl- of 1:1;

Step 3, the solution obtained in step 2 is transferred to the reaction vessel, and then the reactor is placed in a box heat treatment furnace at 180 ° C hydrothermal reaction for 8-12h;

Step 4, after step 3 hydrothermal reaction, take out air cooling to room temperature; take out the precipitate together and the supernatant overnight, centrifuge, centrifuge speed 7000-9000 rev / min, each centrifugation time 20-30 minutes, respectively with deionized water and alcohol Wash 2-3 times;

In step 5, the powder washed in step 4 is placed in a dry box and dried at 60 ° C to obtain a light green tungsten oxide powder.

The simple hydrothermal preparation method is used to synthesize urchin-shaped tungsten oxide from nano-plates and sheets. The machine does not use the solvent to control the morphology during the preparation process, and the subsequent removal of the organic solvent without heating can change the morphology and affect the performance; the obtained urchin-shaped tungsten oxide has good crystallinity, high specific surface area, non-toxicity, no pollution, and low cost, and is expected to have a good application prospect in the fields of photocatalytic degradation of wastewater and photolysis water.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com