Flotation Process Improvement at Room Temperature

- Details

- Category: Tungsten Information

- Published on Saturday, 25 May 2019 21:46

China's tungsten reserves rank first in the world, two-thirds of which are scheelite. However, scheelite is often distributed in fine grains, the grade of raw ore is low, and it often coexists with calcareous gangue minerals with better floatability. Therefore, the separation of scheelite and calcareous gangue minerals has always been a difficult problem in the mineral processing industry.

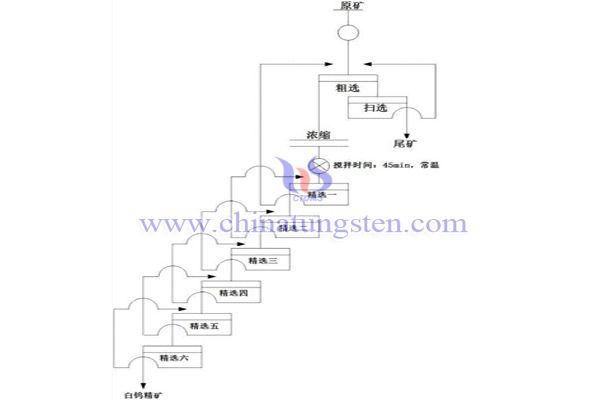

The normal temperature method is to add more sodium silicate to the crude concentrate and stir for a long time at room temperature to inhibit gangue minerals and obtain Scheelite Concentrate through multiple concentrations. The beneficiation cost of this method is low, but its adaptability to ore is not as good as that of heating method. The beneficiation index fluctuates greatly and contains high impurities. Usually, the qualified Scheelite Concentrate with WO3 65% can be obtained by hydrochloric acid leaching. In order to solve the shortcomings of normal temperature flotation, some scholars adopted the following measures:

(1) Sizing:

Scheelite raw ore is allocated into slurry of 30-35% concentration and injected into flotation machine to adjust slurry pH to 7-11.

(2) Rough selection:

The slurry QTS-01 is added to the slurry after step (1) to inhibit calcium bearing gangue minerals. After mixing 2- 15min, the collector is added to roughcast and the scheelite rough concentrate and coarse tailings are obtained.

(3) Sweep:

A collector is added to the coarse tailings obtained in step (2) and the tailings and the cleaning concentrate are obtained by one sweep, and the sweeping concentrate is returned to the rough separation.

(4) Six selections:

Concentrate Scheelite Concentrate to 50-70%, add QTS-01 inhibitor, stir at room temperature for 30-60 minutes, add collector, then concentrate once, concentrate twice, tailings return to roughing once, continue to concentrate five times, the final concentrate is scheelite.

Compared with the traditional normal temperature flotation method, the improved process improves resource utilization, reduces environmental pollution, greatly reduces production costs, avoids safety accidents, realizes clean production and improves economic benefits of enterprises.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com