A Preparation Method of Two-dimensional Zinc Tungstate Nanosheets by Microwave Irradiation

- Details

- Category: Tungsten Information

- Published on Friday, 24 May 2019 23:58

Zinc tungstate has high photocatalytic activity and excellent single crystal scintillation properties; thus, it is one of the most promising photocatalysts and high-energy physical scintillation materials. It possesses a high potential to applicate in photocatalytic synthesis and complex ultra-micro device preparation.

Currently, the common methods to prepare zinc tungstate micro/nano materials are: hydrothermal/solvent method, sol-gel method, coprecipitation method, molten salt method and chemical electrospinning method. The product of these methods is mostly zero-dimensional granular, one-dimensional rod/linear, three-dimensional massive structure. For preparation of two-dimensional zinc tungstate material nanosheet, the low efficiency remains a challenge. especially in the preparation of uniform thickness of tungstic acid by templating microwave irradiation is expected to be a possible way to produce zinc nanosheet materials with uniform thickness in higher efficiency.

The soft templating synthesis method has the advantages of peculiar shape of the obtained product and strong regulation of the synthesis process, and has made great progress in the field of nanomaterial preparation, especially the superstructure and pore structure of high-efficiency design and synthesis of specific morphology. Citric Acid (CA) is a kind of organic molecular compound which can be used as a soft templating agent. It has outstanding advantages in regulating material nucleation and inducing orderly growth of materials. In view of the key problems encountered in the preparation of zinc tungstate nanosheets, researchers used CA as the structure-directing agent to prepare two-dimensional zinc tungstate nanosheet structural materials by means of microwave irradiation.

The main processes for preparing two-dimensional zinc tungstate nanosheets by microwave irradiation are as follows:

0.6597 g of sodium tungstate (NaWO4•2H2O) is dissolved in 10 ml of water to prepare a sodium tungstate solution; 0.5949 g of zinc nitrate (Zn(NO3)2•6H2O) and 0.0420 g of CA are dissolved in 10 ml of water to obtain a mixture solution; the previous two solutions are quickly mixed and stirred vigorously for 5 minutes; then, the solution is transferred to a microwave reactor for 30 minutes, and let the resulting precipitate naturally be cooled, and then rinsed with distilled water for 5 times, and washed with ethanol for 3 times. The zinc tungstate nanosheets were prepared by further drying at 80 °C for 48 hours. X-ray diffraction analysis indicated that the phase of the obtained product is ZnWO4.

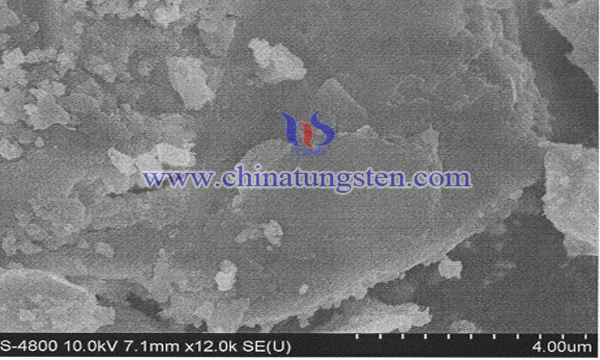

According to the SEM image analysis, the morphology of the product is a nanosheet structure with uniform thickness, regular morphology and high crystallinity. The nanosheet has a thickness of 20-30 nm and a diameter of 2-4 microns. Therefore, it can be seen that the microwave irradiation method has the advantages of mild reaction conditions, simple operation, fast product synthesis rate, good reproducibility, unnecessarily for high-temperature post-treatment, and easy realization of low-cost scale production, and conforms to the new idea of green chemistry.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com