Domestic Titanium Tungsten Powder Preparation Scheme

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 11:46

Vehicle exhaust contains a lot of nitrogen oxides. It not only causes acid rain, photochemical smog and other environmental problems, but also seriously threatens human health. Therefore, how to remove nitrogen oxides efficiently has become an important topic.

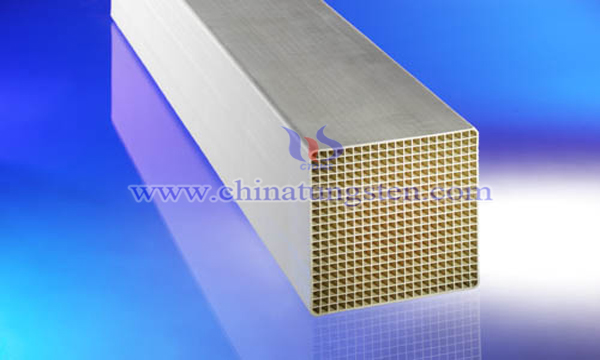

At present, the most popular technology of flue gas denitrification is selective catalytic reduction (SCR) using NH3 as reducing agent. At present, the main application of metal oxide catalysts is mainly supported by titanium dioxide, supported by V2O5-WO3, which we usually call titanium vanadium tungsten catalyst. Ti-W powder as catalyst carrier is the key material for catalyst preparation.

Unfortunately, some data show that the performance and quality of domestic titanium vanadium tungsten catalysts are still inferior to that of imported products from Japan, the United States and Germany. The reason is that the preparation methods of domestic titanium-tungsten powders generally have some defects, such as complicated process, poor dispersion uniformity and easy failure of catalysts.

In order to improve the level of domestic titanium vanadium tungsten catalysts, some scholars improved the manufacturing process of domestic titanium tungsten powder, and finally prepared products with uniform dispersion, low viscosity, good fluidity, good water retention and high catalytic activity.

By optimizing neutralization time, adding ammonia water to excessively neutralize, adjusting pH to 8-9 after neutralization, and heating after neutralization, the improved process can make the product disperse evenly, reduce viscosity, have good fluidity and water retention. The prepared catalyst is easy to form, has high yield, high strength, high activity and stable quality. It has stable catalytic activity and long service life at 320-400 ℃. It avoids the use of surfactants and surface dispersants, simplifies the process and reduces the production cost.

According to some data, it is expected that the demand of denitrification catalyst will reach 500000 m3 from 2010 tO2020. The cost can be saved about 2.2 billion yuan by using self-made titanium-tungsten powder, and the wide temperature catalyst can be popularized. Compared with the existing medium temperature commercial catalyst, the cost can be reduced by about 20%, the emission of NOx can be reduced by about 17 million tons, and the economic loss can be reduced by 27 billion yuan.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com