Nano Tungsten Trioxide Preparation by Electrochemical Anodic Oxidation

- Details

- Category: Tungsten Information

- Published on Sunday, 28 April 2019 21:23

Because of its high chromogenic efficiency and low price, nano tungsten trioxide has always been the preferred electrochromic compound. In addition, as a photocatalytic hydrogen production electrode material, nano-tungsten trioxide has also been widely concerned.

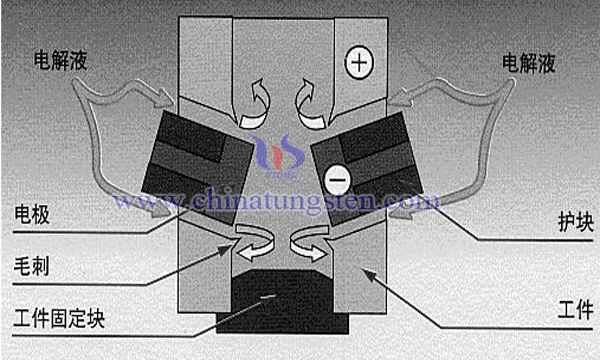

Tungsten trioxide is a semiconductor material with indirect band gap transition. It has good photoelectric and gas sensing properties. In order to make full use of the photoelectric properties of tungsten trioxide, porous tungsten trioxide nanomaterials with regular morphology and large specific surface area need to be prepared. Electrochemical anodization is a low-cost method which can construct porous nanomaterials with adjustable pore size and regular morphology in a large area. Its basic principle is to use high purity metal as anode and another metal or carbon as cathode and put them into electrolyte. Under the action of applied electric field, the ions in electrolyte etch the metal surface of the anode and gradually accumulate into one. Metal oxides with definite morphology and structure. Therefore, the preparation of nano tungsten trioxide materials can be carried out by electrochemical anodic oxidation method. The contents are as follows:

The tungsten wafer is cut into 3 *3 cm and cleaned; the cleaned tungsten wafer is used as the anode of anodic oxidation, and the cathode is placed parallel in the anodic oxidation pool with platinum sheet; the distance between the two is 5 cm; the 2 M nitric acid electrolyte solution is poured into the anodic oxidation pool; the anodic oxidation pool with electrolyte solution is placed in the constant temperature oil bath pot, and the heating is opened to raise the temperature of the oil bath. Firstly, the voltage between cathode and anode is kept for 30 minutes at 80V, then the voltage is swiftly adjusted from 80V to 75V, maintained for 20 minutes at 75V, swiftly adjusted from 75V to 70V, maintained at 70V for 20 minutes, swiftly adjusted from 70V to 60V, maintained at 60V for 20 minutes, swiftly adjusted from 60V to 55V, maintained at 55V for 10 minutes, and swiftly changed from 55V to 50V. Hold for 10 minutes at 50V, quickly adjust the voltage from 50V to 40V, keep for 10 minutes at 40V, quickly adjust the voltage from 40V to 30V, and keep for 1 hour at 30V. After the reaction, the anode material was removed, washed with deionized water and dried with nitrogen. The anode material was placed in OTF-1200X vacuum tube furnace, and the temperature in the tube was raised to 650 ℃ at a heating rate of 5 ℃/min in oxygen atmosphere. The anode material was maintained for 3 hours and cooled to room temperature.

Tungsten trioxide nanoparticles were prepared by electrochemical anodic oxidation. The size of these nanoparticles was 400-500 nanometers long and 40-50 nanometers thick. The gap between nano-massive tungsten trioxide nanoparticles was 200-500 nanometers. The finer structure of nano-micron structure makes the surface area of tungsten trioxide thin film electrode larger than that of tungsten trioxide thin film provided by traditional technology, thus obtaining better photoelectric performance and hydrogen production rate per unit area.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com