Fibrous Tungsten Carbide Nanoparticles Synthesis

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 April 2019 21:40

Tungsten carbide is the main raw material for the manufacture of cemented carbide products, and its particle size has a decisive influence on the properties of cemented carbide products. The preparation of nano-tungsten carbide has become the main way to improve the strength and toughness of cemented carbide products. Cemented carbide is brittle material. There is a contradiction between its hardness and strength. High hardness leads to low strength, while high strength leads to low hardness.

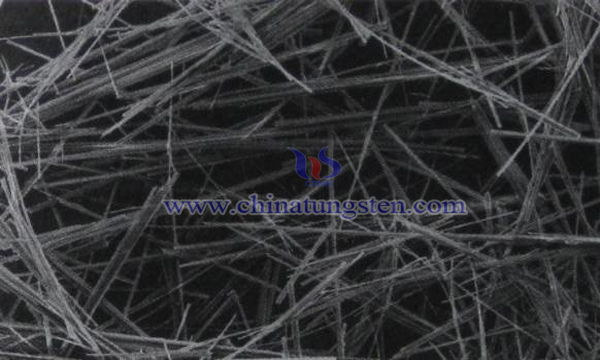

Because nano-tungsten carbide is easy to agglomerate in the synthesis process leading to particle growth and grain growth in the sintering process, how to solve the problem of agglomeration in the synthesis process can solve this problem. For example, some scholars have developed a synthesis method of fibrous nano-tungsten carbide. Because of the special structure of tungsten carbide, the problem of particle agglomeration can be basically ignored. The process is as follows:

(1)Carbon nanotubes and tungsten oxide powder were added into ethanol solution at the weight ratio of 1:3 50 and dispersed in ball mill to make carbon nanotubes and tungsten oxide powder mix evenly.

(2)Filtrating the dispersed solution of carbon nanotubes and tungsten powder, vacuum drying and drying the powder into a high temperature carbonization furnace, heating the carbon nanotubes surface atoms and tungsten reverse in hydrogen reduction atmosphere at 500-700 for 2-10 hours, reducing tungsten oxide, then heating the carbon nanotubes at 1000 1500 above in reduction atmosphere, and holding the tungsten reverse in argon atmosphere for 3-20 hours. Tungsten carbide should be formed, and the inner layer of carbon nanotubes should keep the original structure. The surface layer is tungsten carbide and the inner layer is carbon nanotubes.

In the scheme, several to dozens of tungsten carbide layers are formed on the surface of carbon nanotubes by the reaction of carbon nanotubes and tungsten. The inner layer of tungsten carbide is still fibrous and its diameter can be controlled to 10-100 nm. The nano-tungsten carbide prepared by this method not only keeps the high hardness of tungsten carbide, but also keeps the high strength and toughness of carbon nanotubes. Tungsten composites completely solve the contradiction between the strength and hardness of cemented carbide products. The final product can be used in cemented carbide production or in place of platinum catalyst.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com