How to Prepare Porous Tungsten Trioxide Thin Film Electrode

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 22:37

In the worsening global situation of greenhouse effect and environmental pollution, photocatalytic hydrogen production using solar energy, which is rich in nature, is one of the new energy ways for sustainable development. Photoelectric catalytic water decomposition is used to produce hydrogen from solar energy and water. There are no by-products, and hydrogen and oxygen can be obtained at the two poles separately without pollution, showing strong advantages and development potential.

In order to improve the efficiency of hydrogen production, it is necessary to optimize the various factors of the photocatalytic hydrogen production system, especially the photocatalytic electrode materials. Tungsten trioxide has always been the preferred electrochromic compound because of its high chromogenic efficiency and low price. In addition, tungsten trioxide has been widely concerned as a photocatalytic hydrogen production electrode material.

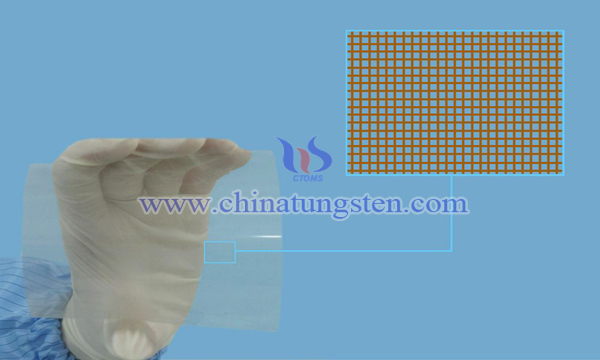

Tungsten trioxide is a semiconductor material with indirect band gap transition. It has good photoelectric and gas sensing properties. In order to make full use of the photoelectric properties of tungsten trioxide, porous tungsten trioxide nanomaterials with regular morphology and large specific surface area need to be prepared. Electrochemical anodization is a low-cost method which can construct porous nanomaterials with adjustable pore size and regular morphology in a large area. Its basic principle is to use high purity metal as anode and another metal or carbon as cathode and put them into electrolyte. Under the action of applied electric field, the ions in electrolyte etch the metal surface of the anode and gradually accumulate into one. Metal oxides with definite morphology and structure. Therefore, electrochemical anodization can be used to prepare porous tungsten trioxide film electrodes.

The porous structure of the prepared porous tungsten trioxide film electrode is similar to that of the depression structure under SEM. The diameter of the hole is about 8-12 microns. This may be due to the etching of the tungsten trioxide film caused by the intense electrolysis process at high current. The finer structure of the nano-micron structure makes the surface area of the tungsten trioxide film electrode three times larger than that provided by the existing technology. The tungsten oxide film has a larger surface area, which leads to better photoelectric properties and hydrogen production rate per unit area.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com