Ferric Oxide-Tungsten Disulfide Nano Composite Lubricant

- Details

- Category: Tungsten Information

- Published on Friday, 05 April 2019 19:49

With the deepening of human exploration into space, more and more space vehicles are sent into space. NASA pointed out that the abnormal or failure of spacecraft due to lubrication failure has become an important factor affecting the effective service time of spacecraft. Therefore, how to maintain good lubrication of key components of spacecraft is a very important issue.

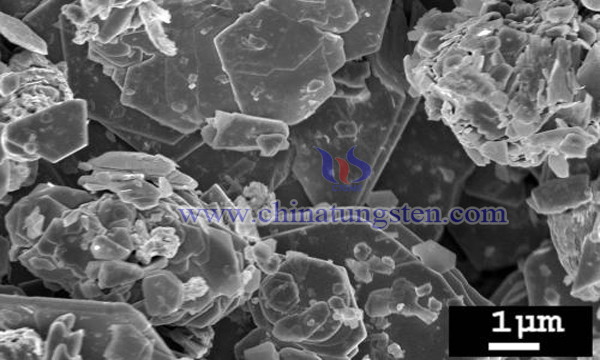

It is found that nano-Fe3O4 is a kind of ferromagnetic nano-particles, which can be magnetized in the friction process of ferromagnetic friction pairs, so it can be firmly adsorbed on the friction interface. If nano-Fe3O4 and WS2 Nano-sheets can be compounded, a new nano-composite lubricant may be formed and the lubrication aging of WS2 Nano-sheets can be prolonged.

Hydrothermal synthesis was used. First, tungsten disulfide was milled to an average particle size of less than 5 micron, then 2.48 g of tungsten disulfide was added to 20 mL glycerol for wetting, then 80 mL glycerol was added for ultrasonic dispersion. The ultrasonic dispersion time was 22 hours, the temperature of ultrasonic dispersion was 110 ℃, the centrifugal time was 10 minutes, and the centrifugal speed was 3000rpm. The undissolved particles at the bottom were removed, and the glycerol content of tungsten disulfide nanosheets was obtained by collecting the upper solution scattered liquid;

In the glycerol dispersion solution of tungsten disulfide nanosheets, 0.134g sodium oxalate, 0.540g ferric chloride hexahydrate and 4.08g sodium acetate were added in turn. After ultrasonic dispersion, the hydrothermal reaction was carried out. The temperature of ultrasonic dispersion was 85 ℃, the time of ultrasonic dispersion was 1 h, the temperature of hydrothermal reaction was 160 ℃ and the time of hydrothermal reaction was 20 h. After cleaning with acetone, the tungsten disulfide-ferric oxide was obtained by drying. The drying temperature of nano-composite lubricant is 50 C and the drying time is 4 h.

The effective lubrication time of tungsten disulfide nanosheets on the friction surface can be significantly prolonged by means of the magnetism of Fe3O4 nanoparticles. In addition, Fe3O4 nanoparticles can form micro-ball effect on the surface of tungsten disulfide nanosheets, thus further improving the lubrication effect of tungsten disulfide nanosheets. At the same time, through the control of preparation conditions, the product yield of Fe3O4-Tungsten Disulfide nano composite lubricant is high, the dispersibility is good, the preparation cost is low, the preparation process is safe, the process is simple and easy to scale production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com