High Density Tungsten Oxide Material for Manufacturing Tungsten Targets

- Details

- Category: Tungsten Information

- Published on Friday, 29 March 2019 23:17

Tungsten oxide film is a widely studied functional material. It has excellent short-wave transmittance, and its band gap can be easily adjusted by doping. Through ion implantation, ultraviolet photon irradiation and gas molecular adsorption, its optical and electrical properties will change significantly. Therefore, it has wide application prospects in optical glass, flat panel display, photoelectric conversion, electrochromic, photochromic and other fields.

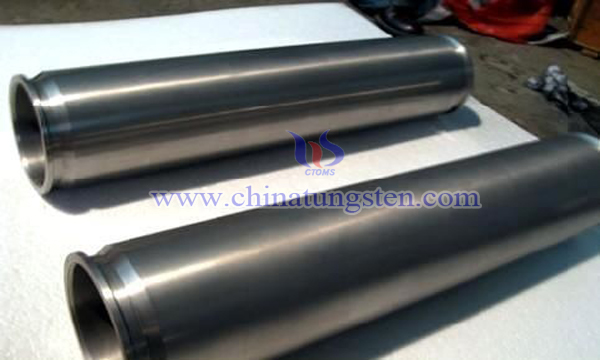

In order to prepare tungsten oxide thin films by physical vapor deposition, dense tungsten oxide target is used. Tungsten oxide in tungsten oxide target is bombarded and gasified by energy beam, and then deposited on the surface of the substrate. Due to the low self-diffusion coefficient of pure tungsten trioxide and melting at about 1470 ℃, it is difficult to sinter compactly. If sintering additives are added, the photoelectric properties of vapor deposited tungsten oxide films are affected by impurities.

In order to improve the density of target materials, researchers have developed a new manufacturing method of highly dense tungsten oxide materials. It is characterized by densification of tungsten oxide sintering without any sintering additives, so that the purity and density of the sintered tungsten oxide are higher than 99% and 6.7g/cm3 respectively. Because of its high purity and high density, this dense tungsten oxide material is suitable for tungsten oxide coating target. The process is not complicated.

Tungsten trioxide powder (average size 17 micron) mixed with 1-5% (weight) polyethylene glycol (PEG) was wet milled in ball mill for 24-96 hours with distilled water. After drying and sieving, it was pressed under 100-200 MPa pressure. After removing agent, the silicon-molybdenum rod furnace in high temperature furnace was sintered in air at 1100-1400 C for 60-180 minutes, and then cooled with the furnace. The purity was higher than 99% and the density was higher than 6.75g/cm3.

The advantage of the preparation process is that it is suitable for both ordinary tungsten oxide powder raw materials (powder size 5-30 microns) and ultra-fine tungsten oxide powder raw materials (less than 5 microns). The key point is that high purity and high density sintered tungsten oxide can be prepared without any sintering additives. This sintered tungsten oxide can be made into various complex shapes economically and efficiently.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com