Tungsten Vanadium Titanium Denitrification Catalyst Regeneration Strategy

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 February 2019 21:11

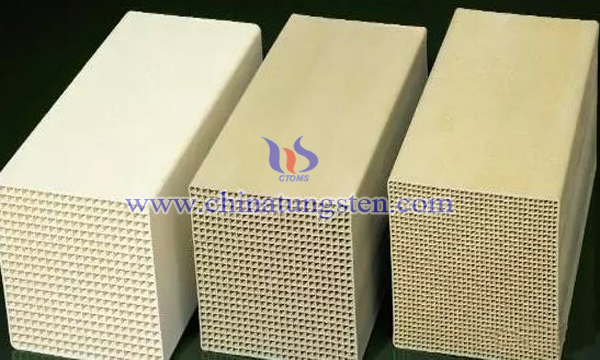

Selective Catalytic Reduction (SCR) flue gas denitrification technology has the advantages of high denitrification efficiency, good selectivity, maturity and reliability. It is widely used in thermal power plants and is the mainstream of denitrification in coal-fired units. The main active components of catalysts used in SCR denitrification are titanium dioxide, V2O-, WO3 and MoO3, which account for more than 90% of the catalyst composition.

Selective Catalytic Reduction (SCR) flue gas denitrification technology has the advantages of high denitrification efficiency, good selectivity, maturity and reliability. It is widely used in thermal power plants to recover waste tungsten vanadium titanium denitrification catalyst and turn waste into treasure.

1)Crushing: crushing the scrap SCR catalyst to more than 150 meshes;

2)Deimpurity removal by water immersion powder: the crushed waste SCR catalyst is immersed in 3-4 times volume of water to remove the adsorbed arsenic, mercury, alkali metal salts and organic substances. The filtered wastewater is recycled after adsorption of arsenic, mercury and organic substances by activated carbon.

3)Leaching: After removing impurities, wet powders are added with 4-6 times volume alkali solution with 60-80 wt% concentration, heated to 140-150 ℃ and soaked for 3-5 hours to make titanium dioxide, V2O-, WO3 and MoO3 sodium, and to form NaVO3, Na2WO4, Na2MoO4 solution and Na2Ti3 cake precipitation. Na2Ti3 cake precipitation is removed by filtration.

4)Recovery of alkali: Step 3) The filtered liquid is heated and concentrated to 1/5-1/15 of its original volume, and the solid alkali is precipitated. After filtration, the solid alkali is reused and the filtrate enters the next process.

5)Silicon removal: Step 4) The filtrate after filtration is adjusted to pH value of 7-8 under boiling condition, boiling for 10-30 minutes, filtering, cake is silicic acid;

6)Tungstate reunification: step 5) The filtrate after filtration is adjusted to pH value above 10 under boiling condition, boiling for 0.5-5 hours, reaching a unified tungstate WO42-; it is the mainstream of denitrification in coal-fired units. The main active components of catalysts for SCR denitrification are titanium dioxide, V2O-, WO3 and MoO3, which account for more than 90% of the catalyst composition.

7)Sedimentation of wolframic acid: The filtrate of step 6 is added to 8-12 mol/L nitric acid of equal volume at 60-80 ℃, then cooled and filtered to obtain WO3·2H2O of wolframic acid.

This method only needs one alkali leaching without calcination process, only needs about 145 ℃ and 70 wt% concentrated alkali solution to soak for 4 hours, then tungsten trioxide can be completely sodium-oxidized, tungsten and vanadium in waste catalyst can be formed into Na2WO4 and Na2VO3, and low content tungsten trioxide can be completely converted into tungstic acid, tungsten trioxide can be recovered more than 99 wt%, wastewater can be straight discharge.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com