The Similarities and Differences Between WEDM-HS, WEDM-LS and WEDM-MS

- Details

- Category: Tungsten Information

- Published on Monday, 05 November 2018 10:29

The Similarities Between WEDM-HS, WEDM-LS and WEDM-MS

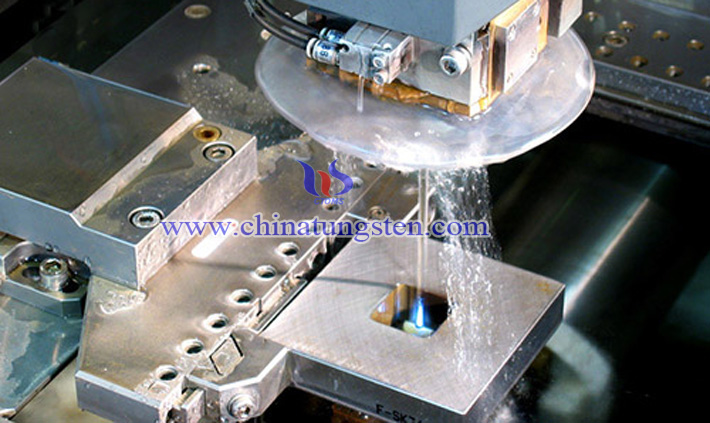

WEDM-HS, WEDM-LS and WEDM-MS all refer to - EDM machine - a CNC machine tool that can remove metal and complete workpiece cutting tasks. The full name of the electric discharge wire cutting machine Wire-cut Electrical Discharge Machining,English abbreviation is WEDM. From another point of view, it can also be said that the WEDM-HS, the WEDM-MS, the WEDM-LS are all metal wire and metal discharge corrosion processing.

The Differences Between WEDM-HS, WEDM-LS and WEDM-MS

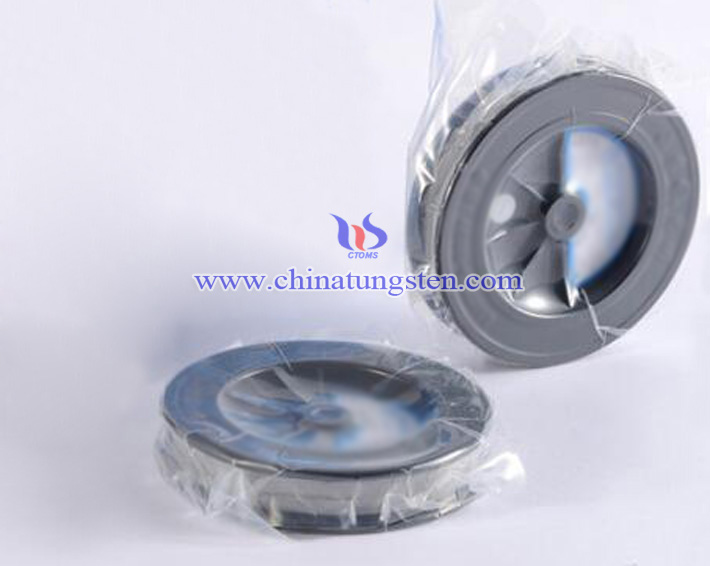

WEDM-HS It is China's original EDM wire cutting processing mode. The WEDM-HS is generally made of molybdenum wire. The WEDM-MS – the upgrade of the WEDM-HS, can also be said to have evolved from the WEDM-HS, and the wire is also a molybdenum wire. However, compared with the molybdenum wire used in the WEDM-HS, the medium wire molybdenum wire is relatively higher in price. In addition, the price of the WEDM-MS machine is relatively high. In addition, the fast-moving molybdenum wire can be reciprocally processed, that is, it can be reused. In addition, it is very important that the processing speed of the WEDM-HS is relatively fast, that is, the processing efficiency is relatively high, and the required production cost is relatively low. However, correspondingly, the processing accuracy of the WEDM-HS machine is not good. The surface roughness of the WEDM-HS products is also relatively poor.

As mentioned before, the WEDM-MS is developed from the WEDM-HS, so its basic processing principle is the same as the WEDM-HS. The WEDM-MS has greatly improved the shortcomings of the original WEDM-HS processing quality on the basis of the characteristics of simple structure, low cost, good process effect and low consumption in the process. The surface roughness of the medium-traveled product can reach R0.8.

One of the wire-cutting industry's masters said: "The cutting speed of the WEDM-MS is not slower than the WEDM-HS, but it is higher than the WEDM-HS. It only reduces the cutting speed to achieve the cutting effect in the process of multiple cutting. That is to say, the WEDM-MS is not the highest efficiency, but the average efficiency. In addition, the quality of the WEDM-MS processing tends to be slow.

He also said, "The WEDM-MS, with the quality of WEDM-LS, but only need the price of fast!"

The wire-cutting master also lamented: "The WEDM-MS can be said to bring a revolution to the mold industry."

The WEDM-MS with multiple cutting functions combines the advantages of both WEDM-HS and WEDM-LS. It is reasonable to say that it should be the most used in the wire cutting industry and the “mainstream” of the wire cutting industry. But in fact, the author listened to friends from the industry engaged in wire cutting. In fact, nowadays, there are more to use.

Next, let's talk about the WEDM-LS that is not a molybdenum wire for the wire. The wire of the WEDM-LS is made of copper wire, and the copper wire is disposable. That is to say, the wire of the WEDM-LS can only be used once. However, the advantage of WEDM-LS walking is that the processing precision is as high as 0.01 mm or less, and more importantly, the surface roughness of the product is very good, and Ra = 0.8 μm and above can be achieved. The disadvantage is that the price of WEDM-LS-cutting machines is relatively expensive.

Similar to the question "Can the WEDM-MS replace the WEDM-LS?" Wired cutting experts have answered that, to a certain extent, the WEDM-MS can be infinitely close to the WEDM-LS. However, there is still a long way to go before the WEDM-MS has to replace or surpass the WEDM-LS.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com