Three-Dimensional Graphene/Tungsten/Titanium Synthetic Photocatalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 09 September 2018 23:32

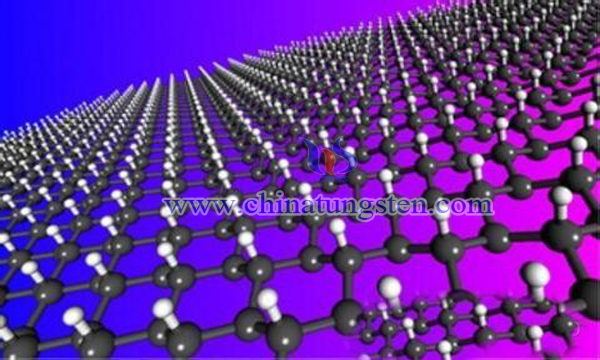

Graphene has special structure and excellent performance. Using graphene as catalyst support can reduce the recombination of photogenerated electron-hole pairs in titanium oxide and improve the photocatalytic performance of titanium oxide effectively. However, due to the forbidden bandwidth of titanium oxide, only the ultraviolet part of sunlight can be utilized.

The main function of graphene in the composite system is to disperse titanium oxide nanostructures and transfer photogenerated electrons, and it has no photocatalytic activity. Therefore, it is necessary to further improve the visible light utilization and photocatalytic activity of graphene/titanium oxide composite. Nanometer tungsten oxide has a large specific surface area, narrow band gap, can absorb sunlight to generate photogenerated electrons and hole pairs, and has a certain photocatalytic degradation ability to organic matter under visible light. The composite of tungsten-based nanosheets and graphene can not only give graphene a certain degree of photocatalytic activity, but also promote the dispersion of graphene, prevent graphene from curling, and improve its reinforcing effect.

Researchers have attempted to fuse the three and proposed a method to fabricate three-dimensional graphene/tungsten-based nanosheet/titanium dioxide layer-by-layer assembly structure.

(1)The tungsten sulfide or tungsten oxide powder of 1-10 g and 0.1-1 g hexadecyl trimethyl ammonium bromide were added into 500-1000 mL deionized water, dispersed by ultrasonic wave for 20-40 min and stirred for 20-40 min to obtain tungsten sulfide or tungsten oxide dispersion solution.

(2)The above steps (1) tungsten sulfide or tungsten oxide dispersions were sheared for 1-3 hours by a high-speed mechanical shearing machine with rotating speed of 1000-8000 r/min under ultrasonic oscillation, and then centrifuged by a centrifuge with rotating speed of 4000-8000 r/min and then stirred for 1-3 hours to obtain tungsten-based nanosheet solution.

(3)Graphene dispersions were prepared by adding 5-15 mL graphene solution of 0.8-1.2 g/L to 30-70 mL deionized water for 20-40 min.

(4)0.1-0.3 g polyacrylic acid or sodium polyacrylate was added to the graphene dispersing solution obtained above (3) and ultrasonic dispersed for 20-40 min to obtain the graphene dispersing solution.

(5)Under stirring and ultrasonic oscillation, the solution of tungsten-based nanosheets obtained in the above steps (2) was slowly added into the graphene dispersion solution obtained in step (4) to obtain the graphene/tungsten-based nanosheet composite dispersion solution.

(6) 2.2-5.5 g titanium dioxide was slowly added to the dispersing solution of step (5) graphene/tungsten nanosheet composite was obtained by stirring ultrasonic dispersion for 15-30 minutes and then transferred to a constant temperature water bath pot at 60-90 ℃.

(7)When the temperature is stable, the solution of oxalic acid with concentration of 1~2 mol/L is slowly dripped into 50~100 mL oxalic acid solution under the condition of continuous stirring, and the colloid is formed. Then the colloid is dried in a drying oven at 70~90 ℃, and the three-dimensional graphene/tungsten nanosheet/titanium oxide precursor powder is obtained by grinding.

(8)Three-dimensional graphene/tungsten-based nanosheets/titanium oxide precursor powders obtained in step (7) above were calcined in a box furnace for 1-3 hours at 400-600 ℃ under nitrogen protection. After natural cooling and grinding, the three-dimensional graphene/tungsten-based nanosheets/titanium oxide layer assembled structure samples were obtained.

The advantages of this process are that the homogeneous dispersion of tungsten-based nanosheets in aqueous solution is prepared by mechanical shearing method, and the three-dimensional graphene/tungsten-based nanosheets/titanium oxide layer-by-layer assembly structure is obtained in aqueous solution. The preparation process is simple and easy for large-scale production. The single material is more conducive to the separation of photogenerated electrons and hole pairs, thus obtaining high activity visible light photocatalytic materials. The material can be applied to the fields of sewage treatment, photo degradation water, air purification, solar cell and so on.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com