Supported Phosphotungstic Acid Catalyst Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 19 August 2018 23:00

Carboxylic esters are a kind of basic organic chemical raw materials. They are widely used in perfumes, flavors, plasticizers, solvents, resins, coatings, cosmetics, pharmaceuticals, surfactants and organic synthetic intermediates. They have broad market demand at home and abroad.

At present, organic acids and alcohols are used as raw materials and concentrated sulfuric acid as catalyst to synthesize by batch reaction. Concentrated sulfuric acid as a catalyst for esterification has many disadvantages, such as corrosion of equipment, pollution of the environment, long post-treatment process and so on. Therefore, replacing the traditional catalyst for esterification with solid catalyst has become an important catalytic research field.

It was found that the combination of phosphotungstic heteropoly acid H zeolite as esterification catalyst has the advantages of good thermal stability, high activity and good selectivity. It can be used to catalyze the esterification of acetic acid with n-butanol, isobutanol and ethanol instead of strong acid catalysts. It can also be used to catalyze the esterification of lactic acid with n-butanol and to synthesize them separately.

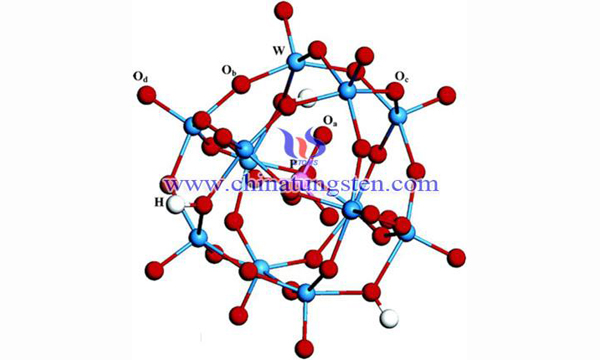

The preparation methods of phosphotungstic heteropoly acid supported catalyst are as follows: Keggin structure phosphotungstic acid is dissolved in deionized water, the pre-treated H beta zeolite is mixed with the above solution, the impregnating medium is deionized water, the liquid-solid ratio of the volume of impregnating solvent to the mass of carrier is 2-5 ml/g, and it is constantly vibrated in a constant temperature oscillator at normal temperature and pressure. The catalyst was prepared by boiling and soaking for 12-24 hours, then temperature-programmed drying, heating up to 100-120 ℃ in 8-12 hours, drying for 1-4 hours at this temperature, calcining and activating for 1-4 hours at 180-220 ℃. Before impregnation, H beta zeolite needs to be roasted for 1~4 hours at 350~450 ℃.

These methods can be used as heterogeneous catalysts directly in esterification reaction. The obtained catalysts can also be added into alumina binder, molding aids, nitric acid, distilled water, and extruded into strips. The strips are dried and dried at 100-120 ℃ for 4-12 hours, and then activated at 400-500 ℃ for 2-6 hours. The obtained catalyst was used for continuous operation of fixed bed reactor.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com