Tungsten Oxide Ceramics Aging Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 March 2018 10:23

The aging process of tungsten oxide ceramics can reflect its anti-aging ability, and its anti-aging ability is mainly determined by the leakage current value of the tungsten oxide ceramics.

The first step of the aging process is to place the tungsten oxide ceramic in an oxygen atmosphere. A voltage of 10 mA was applied across the tungsten oxide ceramic and a leakage current value was collected every 60 seconds. After 12 hours of aging, the tungsten oxide ceramics were measured under air conditions to measure their volt-ampere characteristics.

The second aging process: The tungsten oxide ceramic was placed under a nitrogen atmosphere. A voltage of 10 mA was applied across the tungsten oxide ceramic and a leakage current value was collected every 60 seconds. After 12 hours of aging, the tungsten oxide ceramics were measured under air conditions to measure their volt-ampere characteristics.

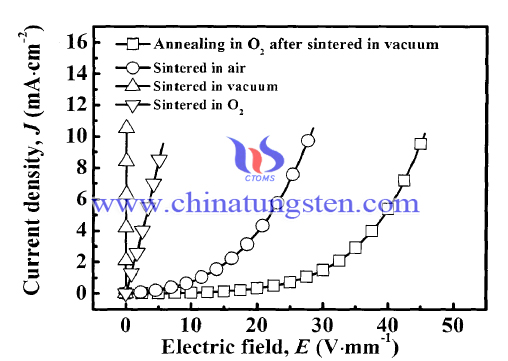

As shown in the figure, during the first aging test, the leakage current change process is like that under air conditions, but it is slightly different. Under an oxygen atmosphere, the leakage current rapidly decreases to a minimum value as the voltage loading time increases. Then it remained stable, and there was no leakage current value of the tungsten oxide ceramic sintered at 1050°C, which first decreased and then increased. Neither did the leakage current of the tungsten oxide ceramics sintered at 1100° C. air slowly decrease.

By measuring the volt-ampere characteristic curve of the tungsten oxide ceramic, the varistor voltage of the tungsten oxide ceramic is found to increase, while the nonlinear coefficient decreases. This shows that the barrier height of the tungsten oxide grain boundary increases and the grain resistance increases. Under the oxygen atmosphere, oxygen reacts with oxygen vacancies through the grain boundaries, which increases the grain boundary barrier. Thus, the leakage current of the tungsten oxide varistor ceramic is reduced, and the varistor voltage is increased. However, the electrons combined with the adsorbed oxygen originate from the crystal grains. As the number of adsorbed oxygen ions increases, the electron concentration in the crystal grains decreases, resulting in an increase in the grain resistance.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com