Bismuth Tungstate Photocatalytic Hydrogen Production

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 March 2018 20:42

Nano thin films have large surface area of one-dimensional nanosheets, and provide direct and smooth transmission paths for photoelectrons and holes. It can effectively promote the electron transport to the material interface. The preparation of a thin film of bismuth tungstate photocatalyst needs the following process:

The FTO conductive glass was followed by ultrasonic 10min in deionized water, acetone and ethanol solution, and cleaned by deionized water and blown to dry.

The 3.32g potassium iodide powder and 0.9702g bismuth nitrate powder were added to the 60mL deionized water. The commercial concentration of nitric acid was adjusted to pH to 1.7 with the volume fraction of 65-68%. Finally, the pH = 1.7 of the bismuth oxiodide nanoscale precursor solution with 0.04moL/L concentration was obtained.

A standard three electrode device was used for the process of cathodic electrodeposition. The FTO conductive glass is used as the working electrode, the platinum electrode is used as the electrode, and the silver / silver chloride electrode is used as the reference electrode. The precursor solution of bismuth oxide nanoscale is used as the electrodeposition solution of the cathodic electrodeposition process. 10min is deposited at the voltage of -0.1V (relative to silver / silver chloride electrode). The bismuth iodide nanoscale film on FTO was obtained.

1.316g sodium tungstate powder was added to 40mL deionized water, and a sodium tungstate ion exchange solution of 0.1moL/L was prepared with the concentration of 40mL. The iodine oxygen bismuth nanosheet film and the iodine oxygen bismuth film face up and slanted in the crystallizing kettle. The ion exchange solution is added. The ion exchange process of 4H is carried out at 120 degrees. The Bi2WO6 nano thin film is prepared, washed with deionized water and dried at room temperature.

The Bi2WO6 films prepared by calcination and calcination conditions for muffle furnace heating speed: 2 ℃/min, heat up to 550 ℃, keep 2h, naturally cool down, and get Bi2WO6 nanoscale film.

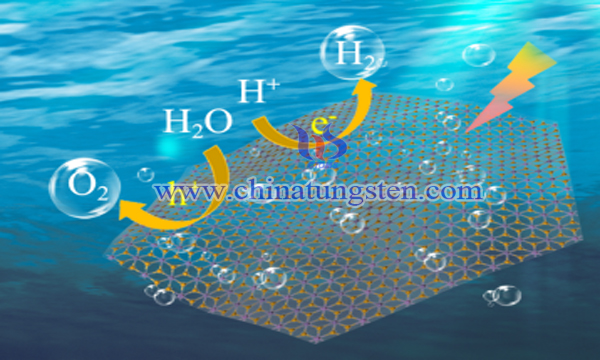

Bismuth tungstate nanocrystalline film can be used as an efficient photoanode material. It can be used for photodecomposition of water and hydrogen production in photoelectrochemical cell. It can efficiently transform solar energy into clean energy, and effectively alleviate the problem of fossil fuel shortage and serious environmental pollution.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com