Determination of Tungsten Carbide with Inductively Coupled Plasma

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 21:22

Hard alloy with high hardness hard tungsten carbide micron metal powder as the main ingredient, with cobalt (Co), nickel (Ni), molybdenum (Mo) as the binder, powder metallurgy products in vacuum furnace or hydrogen reduction furnace in sintering, different tungsten content plays a key role in the performance of the alloy. The detection requirements must be accurate and reliable, the test for the tungsten content of hard alloy mainly has the gravimetric method, colorimetry and atomic absorption spectrometry.

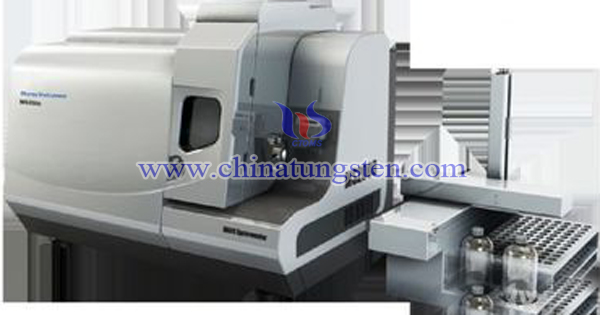

Inductively coupled plasma (ICP) is a new type of chemical method for tungsten content determination in cemented carbide. It is based on inductively coupled plasma atomic emission spectrometry. According to the sample material in gaseous atoms (or ions) are excited, the outer electrons from excited state to return to the ground state, the characteristics of radiation emitted radiation can (different spectra) method to study chemical substances.

A. Blank test:

The hard alloy as the sample; 2 sample from said parallel with the same mass, one as the experimental group, the quality of M0 as a blank control group, the control group test results for m2;

B. Determination:

1) The test sample group and blank control group sample is placed in a beaker;

2) Respectively add enough ammonium sulfate and concentrated sulfuric acid, heating to white smoke, keep 15 ~ 20min to sample completely dissolved sulfate precipitation of tungstate after cooling to room temperature, add enough precipitation;

3)The precipitation was filtered in a group of capacity bottles, and 8~10 times were washed and precipitated with sulfuric acid.

4)Remove the sample precipitate was placed in a porcelain crucible, the two groups of filtrate was diluted with sulfuric acid mixing, blank control group precipitation of ammonia washing 6 to 8 times, and then washed with hot water 60 ~ 80 ℃ 3 to 4 times. After the insolubles were placed in a porcelain crucible, the filtrate was discarded, the two porcelain crucibles were ashed at 300-400 ° C, and then placed in a muffle furnace at 750-760 ° C for 30-50 min and then cooled to room temperature. The scales accurately weighed on the mass m1 and m2, m1 for the test group after burning the quality of tungsten trioxide, m2 is the weight of the blank control group after burning;

5)The sample filtrate on ICP with the work curve determination of strength, instrument automatically calculate the P content of tungsten in the filtrate;

D. The drawing of the work curve:

1) The tungsten standard solutions of 0.0mL, 1.0mL, 2.0mL, 3.0mL, 4.0mL and 5.0mL were removed in a group of 100mL volume bottles to be mixed with the dilute constant volume of sulphuric acid.

2) And solution in the same working condition, at the wavelength of 239.709nm, absorbance measurement standard, with tungsten concentration as abscissa and ordinate intensity of work curve;

E.The calculation of the results:

Calculation of tungsten carbide mass fraction, the results expressed in%;

Compared with the traditional methods for determination of tungsten content of carbide, this method is simple, accurate and reliable advantages, but its shortcoming is that mass spectrometry instruments are expensive.

Inductively coupled plasma (ICP) plasma is a new method for the determination of tungsten content in cemented carbide, compared with the method for determination of tungsten in traditional cemented carbide, this method has the advantages of simple operation and accurate and reliable detection results, but its shortcoming is that mass spectrometry instruments are expensive.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com