ITER Divertor Tungsten Copper Hot Pressing Method

- Details

- Category: Tungsten Information

- Published on Friday, 02 February 2018 15:41

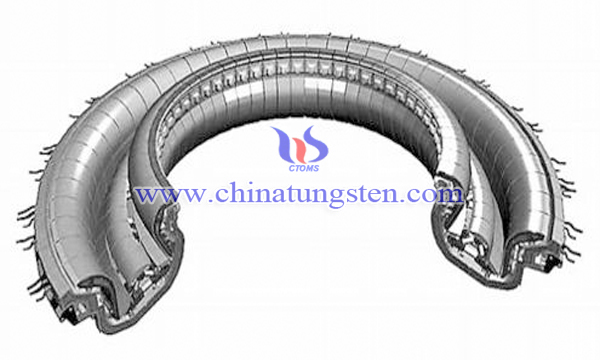

The ITER divertor is a superconducting tokamak can produce large-scale nuclear fusion reactions, commonly known as "artificial sun", is to solve human future clean energy has the potential of scientific project. In this, tungsten filter is an important part of its parts and plays an important role.

Tungsten has become one of the hot candidate materials for fusion reactor facing plasma because of its high melting point, high hardness, neutron irradiation, good thermal conductivity and low activity. Copper has excellent thermal conductivity and conductivity. Its thermal conductivity is 4 times higher than that of powder metallurgy tungsten. It can effectively take away the heat generated during nuclear fusion reaction, and it can be used as heat sink material.

Tungsten has become one of the hot candidate materials for fusion reactor facing plasma because of its high melting point, high hardness, neutron irradiation, good thermal conductivity and low activity. Copper has excellent thermal conductivity and conductivity. Its thermal conductivity is 4 times higher than that of powder metallurgy tungsten. It can effectively take away the heat generated during nuclear fusion reaction, and it can be used as heat sink material.

Tungsten + copper is known as an outstanding industrial heating material. In artificial solar programs, fusion reactor designers and material researchers found that, using copper and tungsten connection modules as Plasma Facing Components (PFCs) that can withstand both high temperature and high-energy particle radiation from the plasma, they also carry away as much heat as possible on the tungsten.

The close connection between tungsten and copper is the key to the acquisition of PFC. Due to the great difference of thermal expansion coefficient between tungsten and copper, the thermal stress of welding is very large. And there is almost no solid solution between tungsten and copper. In addition, the melting point of tungsten and copper is also very different. Therefore, the traditional welding methods, such as diffusion welding and brazing, are not suitable for the welding of tungsten and copper.

Therefore, to find effective ways to the surface of the tungsten copper welding is very important; think over and over again, researchers developed a method for preparing tungsten copper module, by means of combination of deposition and hot pressing, copper can be welded to the surface of tungsten. After further processing, tungsten and copper modules of various shapes and sizes can be obtained, for example, tungsten and copper modules for divertor of Tokamak fusion device.

Tungsten copper cladding and hot pressing method using a combination of the required equipment is simple, has low production cost, simple operation, easy control of technological parameters, high efficiency etc., it is not only suitable for high-tech research such as ITER, but also suitable for mass production of tungsten copper alloy in ordinary industry. After the copper is welded to tungsten, further mechanical processing can be carried out to obtain the required shape and size of the tungsten copper module. This method reduces the difficulty of tungsten copper welding, improves the flexibility of subsequent processing, and can produce a complex tungsten copper module with a complex shape.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com