Sintering Driving force - Surface Energy

- Details

- Category: Tungsten Information

- Published on Wednesday, 31 January 2018 22:22

The driving force of the tungsten carbide powder mainly comes from the reduction of the excess free energy of the system. Free energy can be divided into surface energy and lattice distortion energy, in which the reduction of surface energy plays a leading role in the sintering process.

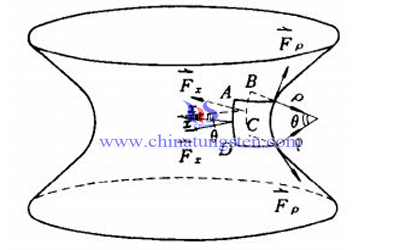

It is difficult to calculate the driving force because of the complexity of the sintering system. However, it can be derived by a simplified sintering model. Kuczynski's two-ball model is one of the most famous simplified models.

Extracting unit surface ABCD from the neck surface. And the radius of curvature of P and X sintering neck forming the same angle. The coordinate system is set up, let X be a positive, P is negative, calculation formula of surface tension Fx and Fρ are as follows:

Fx=γAD=γBC

Fρ=γAB=γDC

AD=ρsinθ

AB=xsinθ

γ-- surface tension. When θ is small, sinθ≈θ,so

Fx=γρθ

Fρ=-γxθ

Resultant force of vertical action on ABCD

F=2(Fxsinθ/2+Fρsinθ/2)=γθ2(ρ-x)

The ABCD area is xρθ2. Stress on the top

σ=F/(xρθ2)=γ(1/x-1/ρ)

x>>ρ

So, σ=-γ/ρ

Minus sign means stretching force, of which the direction towards the outside.

Gas in the pores will prevent pore contraction and further growth of the sintered neck. Therefore, the difference between the pressure Pv of the gas in the pore and the tensile stress of the surface is the effective Ps: that promotes the sintering of the pore net.

Ps=Pv-σ

When the pores are connected to the surface of the particles, that is, the opening of the pores, Pv should be 1 atmospheres, that is, 0.1MPa. Therefore, only when the sintering neck P increased, and the surface tension decreased to Pv, the stopped process of sintering shrinkage.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com