Mechanical Properties of Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 January 2018 16:51

In order to make full use of the properties of the tungsten carbide, it is necessary to choose a reasonable carbide grade according to the working condition. Therefore, the mechanical properties of the tungsten carbide should be understood. Usually, hardness, flexural strength, compressive strength, abrasion performance, and so on are several important mechanical properties.

1, Hardness

The hardness of the cemented carbide is closely related to the grain size of WC and the content of cobalt. With the increase of cobalt content in the alloy, the hardness will decrease. In the case of the same cobalt content, the smaller the grain size, the higher the hardness. When the use of the mould is different, and the requirement of the hardness is different.

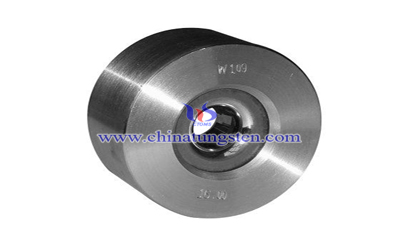

For example, the wire drawing die needs higher hardness, so it is mostly made of low cobalt tungsten carbide. Mold with high impact resistance such as cold heading, cold die and sizing die needs better impact toughness, so the high cobalt mold will be selected.

2, Strength (Flexural Strength)

The strength of a hard alloy is generally expressed as a bending strength, which is a performance indicator of toughness. Flexural strength increases with the increase of the content of the drill. The bending strength of the coarse grain alloy is higher when the content of the drill is low to medium. When the content of the drill is high, the bending strength of the fine grain is higher.

3, Compressive Strength

Compared with other mold materials, the compressive strength of the tungsten carbide is very high, which can reach 340-600Kgf/mm. In the synthesis of artificial diamond anvil high pressure produced, it is necessary to select a kind of alloy with higher compressive strength.

4, Abrasion Performance

Good wear resistance is the most popular feature of tungsten carbide. Wear resistance of the tungsten carbide is a comprehensive reflection of the hardness, strength and microstructure of the alloy, which can be measured by the steel wheel wear method. During the process of powder metallurgy, the mold will contact the powder particles. If the wear resistance is not good, the life of the die will decrease.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com