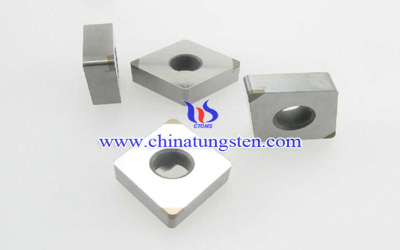

Superfine Crystal Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 January 2018 16:42

Superfine crystal tungsten carbide powder’s arch bridge effect is large, and the relative surface area, the relative density of the blank and the density are not uniform, and the larger pore and particle agglomeration are easy to appear. And, the above problems need to be improved by adopting the appropriate mixture preparation process and the pressing - sintering process.

Powder density of ultrafine tungsten carbide mixture is small, and the arch bridge effect between powder is large. When pressing, it is characterized by low density of blanks, low lamination pressure and low relative density and uneven density of conventional tungsten carbide.

More pressing pressure must be used to suppress the strength of blank strength to reach the conventional powder. However, the large pressing pressure has greater elastic aftereffect in the alloy, and the cracks are prone to crack, delamination and edge drop. This is especially true for complex products.

Therefore, considerable strength in the pressing superfine alloy powder pressing conditions properly reducing pressure and increasing the holding time, thereby reducing the blank pressing defect, but the density of conventional powder compaction density is small, compact and high degree of residual pore.

Hole

Under the final firing temperature, the amount of Co is less, which makes the binder phase fail to completely fill the pores in the alloy and the skeleton clearance between the WC particles, and the pores migrate and finally aggregate into micropores. This hole cannot be solved under the conditions of vacuum sintering.

Rally

In recent years, with the deepening research of ultrafine cemented carbide technology, it is gradually realized that agglomeration of nan powders seriously affects the formability and densification of nanomaterials. However, the agglomeration of nano powders is not only related to the characteristics of the powder itself, but also has an important relationship with the preparation process of the powder.

Obviously, the agglomeration state of the powders obtained by various methods is far away from each other. In the storage process of nanometer powder, various physical and chemical external factors also easily cause the agglomeration between particles. Soft agglomeration particles with loose particles generally will be influenced on the formability. However, the hard pellets, such as tungsten powder and tungsten carbide powder, which are sintered together by high temperature, will be extremely influenced.

In the reduction carbonization process, the particles are close to each other and the particles that are bridged through the cervix have a great influence on the formability of the powder. Especially when the agglomeration particles are sintered together by hundreds of nanoparticles, the pellets have a great influence on the formability and densification of the powder.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com