Densification Mechanism of Warm Compaction

- Details

- Category: Tungsten Information

- Published on Monday, 11 December 2017 19:14

Warm compaction can improve green density and strength. It is generally believed that the densification mechanism of warm compaction is particles re-arrangement and the plastic deformation.

Pressing technology of tungsten carbide cannot obtain high and uniform density. The main reason is that the powder material has poor plasticity or compressibility, high internal stress and elastic aftereffect, and because of friction and other reasons, it can't transmit the pressure more effectively and evenly.

Warm compaction can increase the density. The main reason is that it can improve the lubrication status between powder particles and powder particles and mould wall, affect the elastic and plastic properties of powder, thereby improving the fluidity and compressibility of powder, improving the filling behavior of powder, reducing the pressure loss and increasing the effective pressure.

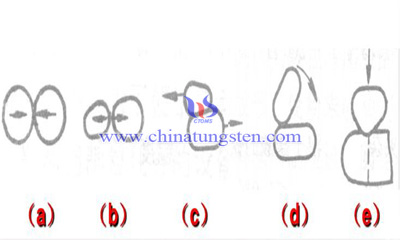

Particles Re-Arrangement

In the early stage of suppression, the rearrangement of particles (as shown above) plays a leading role, and proper plastic deformation provides a coordinated deformation for rearrangement. Reducing all the factors of friction between powder particles are beneficial to the rearrangement process of the powder particles.

Rearrangement process increase the degree of mutual filling between particles, effectively eliminate the pore volume between particles, and facilitate high density of green blanks. In addition, the composition of particle size and the shape of particles all affect the rearrangement of particles. With the smooth surface of the iron particles, the resistance of the rearrangement process is low, and the rearrangement process of powder particles is easy to occur.

The addition of polymers changes the surface properties of the alloy powder, thus reducing the friction between powder and powder and between the powder and the die wall during the pressing process. On the one hand, the former improves the lubricating property between powder and powder, accelerates the rearrangement of powder, and promotes the small powder to fill in the large powder gap.

Plastic Deformation

Low microhardness and small plastic deformation resistance are easy to provide coordination plastic deformation for particle rearrangement and reduce the resistance of particle rearrangement. Therefore, the improvement of the plastic deformation ability of powder particles is another important densification mechanism in the process of temperature and pressure. The effect of temperature on the elastic and plastic properties of the powder material is obvious. With the increase of the pressing temperature, the hardening rate of the alloy powder decreases and the plastic deformability increases, which is beneficial to the plastic deformation of the alloy powder during the pressing process.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com