Warm Compaction: Green Compact Strength

- Details

- Category: Tungsten Information

- Published on Monday, 11 December 2017 19:02

The green compact strength of the tungsten carbide billet is an important parameter of the pressed shape, which can be enhanced by two ways during warm compaction. The first way is to increase the density of the blank by the compacted temperature and pressure, and the two is to affect the polymer itself and its action with the powder particles by the heating temperature.

Green Density

The densification mechanism of the flow thermo pressure process is basically the same as that of ordinary temperature and pressure. But during the warm compaction, the effect of the polymer is obviously stronger than the contribution of the plastic deformation to the density. The densification of the blank has gone through 3 stages.

First, the addition of fine powder increases the filling density. Secondly, during the pressing stage, the mixed powder is first compressed until the binder in the mixed powder is interconnected into a whole. The mixed powder shows good sticky flow behavior in all directions, and the viscous fluid fills the cavity under pressure. Finally, the mixed powder is completely compacted. The repressed semi-finished products can reach a high density.

With the increase of the compact density, the green compact strength has also increased, which can even be 15 ~ 30MPa. During the warm compaction, the polymer is in the viscous flow state in order to have good pressure conductivity and viscosity.

Particle Modification

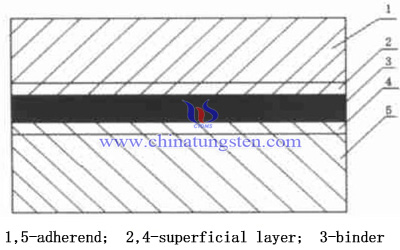

The effect of the binder on the green compact strength can be simplified into a bond model between the two solids in the upper drawing. Even through precision machining, the real contact area between the two interfaces is less than 1% of the total area. The polymer adhesive added between them can play a media role. At this point, the properties of the polymer itself and its interaction with the two solid surfaces determine the bond strength of the two solids.

In order to improve their bond strength, on the one hand, a rigid polymer (polymer with obvious crosslinking trend) can be used. On the other hand, the bond strength between polymer and the adhesive object is improved. The good wettability of the adhesive on the surface of the adhesive is a necessary condition for the interaction between the binder and the surface molecules of the adhesive.

Warm compaction technology is to make full use of the role of temperature. During the pressing process, the forming agent is in the viscous flow state, which ensures the effective contact between the binder molecule and the surface molecules of the sticky surface, and enhances the mechanical connection, physical adsorption, chemical connection and other functions, so as to improve the bonding effect.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com