In Situ Synthesis of Tungsten Carbide Coating

- Details

- Category: Tungsten Information

- Published on Friday, 10 November 2017 23:21

The tungsten carbide ceramics have not only high microhardness but also good wettability with the molten iron, and the wetting angle is close to zero.

In addition, the chemical stability of tungsten carbide ceramic particles, is to enhance the surface of the metal-based coating ideal material.

Compared with fiber reinforced metal matrix composites, tungsten carbide coating composite has the advantages of simple preparation process and low cost. At present, the preparation methods of WC particle reinforced metal matrix surface composites at home and abroad are mainly casting infiltration method, thermal spraying method, powder sintering method, melting casting method, ion infiltration method, surfacing welding method, in-situ synthesis method, etc..

In situ synthesis of tungsten carbide coating is a new method to prepare composite materials recently. The tungsten carbide coating composite prepared by in situ synthesis has three steps.

1. Matrix modulation: Tungsten powder and silicon carbide as raw material, the raw material powder according to a certain proportion in the mortar grinding and mixing evenly, then add the right amount of water glass is modulated into a paste evenly coated on the surface of the substrate.

2. Drying: Paste evenly coated in the air for a period of time, until the surface of the water glass evaporated, the sample was dried in a drying oven, furnace temperature to be controlled at about 100 °C, one hour after the heat with the furnace cooling, the coating of water glass full volatilization.

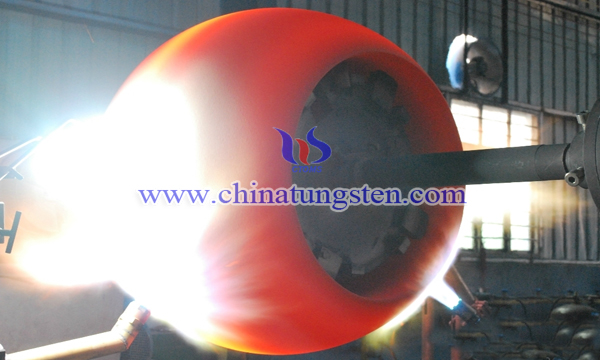

3. The tungsten argon arc is selected as the heat source, and the suitable current heating coating is selected to melt it, which is combined with the base metal. If the current is too large, the viscosity of the coating drops easily after melting, and it is easy to produce grooves and cracks, which is not conducive to the full diffusion of elements and matrix elements in the coating, resulting in a larger hardness gradient and reducing the interfacial bonding strength; If the current is too small, the coating is not completely melted, metallurgical bonding can not be formed with the substrate, and the coating is easy to peel off.

The results show that the high temperature coating can be obtained by in situ synthesis under the condition that tungsten argon arc is heat source. Moreover, the tungsten carbide coating prepared by this method has no pollution on the surface of the reinforcing body, the phase solubility of the matrix and the reinforcing body is good, and the bonding strength of the interface is high, and the process is no longer tedious.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com