Superhard Aspheric Mould Material - Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Thursday, 26 October 2017 11:43

Aspheric optical element is the key component to fabricate micro optoelectronic system. It is necessary to use it for vehicle camera, digital camera lens, etc..

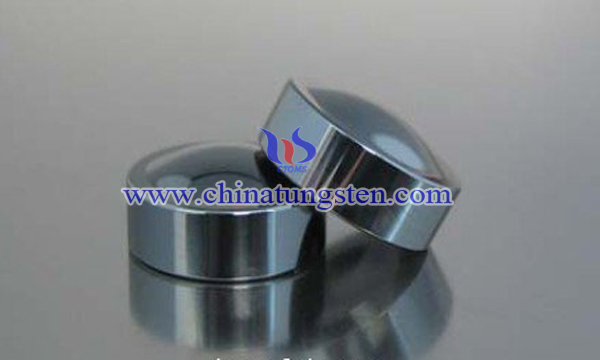

At present, high precision production of aspherical glass based optical elements mainly depends on precision glass molding technology. The ultra precision machining of superhard aspheric dies plays a decisive role in the performance and cost of the final products. In order to prolong the service life of the die, the die material is gradually developed from the die steel to the cemented carbide and precision ceramics. Tungsten carbide is the most ideal raw material for producing aspheric optical devices.

Compared with the precision ceramic mold, tungsten carbide not only has the hardness, high wear resistance and high chemical stability, but also has greater fracture toughness, and its machinability is better; In addition, there is a non bonded tungsten carbide, its greater hardness, abrasion resistance, but also can effectively avoid the phenomenon of decline in the quality of the mold surface by thermal diffusion coefficient Co or Ni bond with hard alloy particles caused by different.

Driven by the demand for aspheric optics, many research institutes at home and abroad have carried out the research on the fabrication of superhard aspheric optical dies. However, tungsten carbide or non bonded tungsten carbide is the main material of this aspheric optical mold. The parallel grinding method and the oblique axis grinding method are used in the ultra precision grinding of aspheric optical mould.

There are many manufacturers to produce aspheric optical elements, but it is no doubt that tungsten carbide is the most ideal superhard mold material for aspheric optical elements. The advantages of tungsten carbide with high hardness and high strength, high chemical stability, high temperature resistance and oxidation makes tungsten carbide die easily ductile grinding, grind, no crack, which are the advantages of other mold materials do not have.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com