Doped Tungsten Doping Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:45

Because blue tungsten oxide powder particles pores and cracks many large surface area , strong adsorption capacity , permeability , chemical activity is good, and in contact with an aqueous solution of a compound having an ion exchange capacity , so the use of blue tungsten oxide doped than doped tungsten oxide doped with better results. Production of tungsten oxide equipment are rotary tube furnace and two kinds. Doped tungsten oxide is tungsten or tungsten oxide doped blue trace hydroxide, alumina. Since the 1960s , many countries have adopted doping process instead of blue tungsten oxide doped tungsten trioxide , thereby increasing the doping effect . In order to make the dopant can be uniformly distributed in the tungsten oxide , the actual production are not used directly , potassium hydroxide, aluminum oxides such insoluble , but with which the decomposition of soluble salts and easy , usually formulated as a potassium silicate and aluminum nitrate ( or aluminum chloride ) was added. Dopant formulations typically within the following ranges ( based on tungsten ) : potassium : 0.3% -0.45 % ; alumina : 0.02% -0.03 % . Doping methods are wet method and the spray French. Wet method in the pot with a steam jacket for evaporation . First, the evaporation pot adding deionized water, was added under constant stirring yellow blue tungsten or tungsten , into a paste, and with stirring , adding potassium silicate solution side , stirred for a while , then add the aluminum nitrate solution , evaporated to dryness moved after drying oven , and finally mixed and sieved .

Spray method is potassium silicate solution was sprayed into the tungsten oxide fine mist ( 80 to 90C) , and continue stirring until basic evaporated to dryness , then a solution of aluminum nitrate was added to the same manner , the final drying , mixing, sieving . Studies have shown that the addition of silicon in the tungsten oxide , potassium aluminum nitrate solution , is not a simple mechanical mixing , but to partially react and generate a multi- tungsten oxide complex tungstate , which generates the same number of characteristics of the substrate , doped miscellaneous agents of the various components and the doping conditions. Tungsten powder and acid preparation is usually used in industrial production hydrogen reduction of tungsten oxide ( blue tungsten oxide or tungsten oxide ) tungsten powder preparation methods . Reduction process, the system depends on the particle size of tungsten powder , particle size composition and oxygen content , potassium content requirements. Often used in a production stage and two-stage reduction to restore two processes . A phase of tungsten oxide reduction is a direct reduction of tungsten powder (D powder ) . Two-stage reduction in two steps : first in the 550-800C will tungsten trioxide or tungsten dioxide reduction of blue tungsten ; Then make tungsten dioxide at 750-900 ℃ reduced to tungsten powder (B powder ) . Reduction is usually in a tubular furnace or rotary furnace . Practice has proved that the particle size of tungsten powder and tungsten trioxide or tungsten blue size is not a simple relationship , with the reduction of different specifications , either coarse or fine tungsten trioxide or blue tungsten powder, tungsten can get crude fine powder or tungsten powder, tungsten powder particle size depends largely on the particle size of tungsten dioxide .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

the R & D Process Doped Tungsten

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:42

Until 1909 , the U.S. General Electric Company Coolidge (wDcoolidge) via powder metallurgy tungsten billet was then produced by machining ductile at room temperature with a tungsten filament , thereby laying the foundation tungsten processing industry , also laid the foundation powder metallurgy . However, this " ductility " tungsten filament in the light bulb lit showed significant brittleness. In 1913, Ping Qi (Pintseh) invented the thorium tungsten wire ( thorium oxide content of 1 % to 2% ) , so that the incandescent filament fragility greatly reduced. Initially, the filament sag ( see tungsten Hang sagging performance ) is not a problem , because the filament is straight wire , but after 1913 , Langmuir (Langmuir) will be replaced by straight wire spiral wire , so that when the light bulb when used , the high operating temperature and weight of the role of the filament sag, thus pure tungsten and tungsten are difficult to meet community requirements . In order to solve tungsten droop and short life and other issues, in 1917 , Perth (A.Pacz) invented the high temperatures , " no deformation " of the tungsten filament . At first, he used when in the preparation of pure tungsten Woe roasting fire tower tungsten trioxide , stumbled with this reduction of tungsten trioxide proceeds made from tungsten powder tungsten spiral , after recrystallization exception mysteriously no longer droop.

Then, after 218 repeated experiments , he finally found that adding potassium tungstate and sodium silicate , after reduction , pressing, sintering and processing the obtained tungsten wire , a fairly coarse recrystallized grain structure neither soft and anti- sagging, this is the earliest non- sag tungsten wire . Perth discoveries laid the basis for the production of non- sag tungsten , until now, the United States does not sag tungsten wire is still called " 218 tungsten wire " to commemorate this major discovery in Perth . However, the first production does not sag tungsten filament brittle than male serious that some insist on using Vitex tungsten bulb factory for the filament. But with no sag tungsten production process of continuous development and improvement , people gradually realized by simultaneously adding the potassium tungsten oxide , silicon, aluminum compounds , can make the tungsten filament at high temperatures with a good anti- sag performance, but by then after crystallization has satisfactory ductility at room temperature . This is now commonly known as "AKS tungsten wire ," or " does not sag tungsten wire " or " doped tungsten wire ." It has many excellent properties , and become the electric light and electronic industries as an important base material . A brief history of the development of tungsten industry from the outset with the light bulb industry closely linked . In 1878 , Edison (TA Edison) invented the carbon filament light bulbs. But this lamp there is a serious disadvantage , primarily life is too short .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Doped Tungsten Production Processes

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:39

Carolina (T.Millner) in 1931 will this improvement does not sag effect is known as "GK effect ." Then mixed tungsten -doped tungsten production process lengthy production processes , including tungsten smelting, processing of powder metallurgy and plastic preform several major phases . Preparation of tungsten billet billet production of tungsten used usually prepared by powder metallurgy , which includes the preparation of tungsten oxide , doped tungsten powder preparation , pickling, and pressure- sintering process . Preparation of tungsten oxide doped tungsten production is usually chosen by Jones Lang tungstate (APT) as raw materials . Preparation paratungstic from tungsten acid Holderness addition to traditional classical technique , but in the 1950s the international community to carry out extraction and ion exchange method of research, China in the 1970s also used these processes , thereby simplifying the process, improved recovery of tungsten . Industrial preparation of tungsten oxide in two ways :

(1) At a temperature of 500 to 800 ℃ calcined paratungstic acid obtained by the yellow tungsten trioxide ;

( 2 ) Temperature at 400 to 600C in a reducing gas atmosphere at reduced paratungstic acid blue tungsten oxide .

Blue tungsten oxide there is no fixed formula and uniform chemical composition , the main phases money tungsten bronze (ATB) and tungsten oxide . Followed tungsten trioxide , in a reducing atmosphere at a higher temperature will appear in the carbon filament yarn and buttons are spades replaced wire , but thallium low melting point, and thus the operating temperature and luminous efficiency is low . 1903 , according to Jay zafirlukast (A.Just) and Hannah door (F.Hannaman) patents, Hungary for the first time to create a tungsten filament. It is the carbon filament of hydrogen containing tungsten oxyhalide steam heated to high temperatures by the current , the carbon was completely replaced tungsten . Incandescent filament thus obtained contain more or less of carbon , not brittle quite serious , and in the use of the lamp , the filament continued densification , and thus the electrical parameters of the filament will change . In 1904, Jay zafirlukast and Hanna door recognizes the impact of carbon on the brittleness , using carbon- tungsten compound is mixed with a binder , and then extruded into filaments , and then heated in hydrogen reduced to metal . This method is very brittle tungsten obtained , but because of its much better light efficiency , or replacing the carbon filament , hungry for the production of filaments and filament lamps bear . These methods are not prepared thin tungsten wire. To solve this problem , in 1907 , a low nickel content of the tungsten alloy available, it is prepared by machining , but serious brittleness hindered its application .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Detect A Fake Tungsten Gold Bar

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 13:48

Detecting a high-quality fake tungsten gold bar would be extremely difficult. It would likely require significant and material alterations to the bar being tested and this would negatively affect the marketability if its hallmark veracity were vindicated.

This is likely a reason why page Page 11 of the GLD prospectus states “Neither the Trustee nor the Custodian independently confirms the fineness of the gold allocated to the Trust in connection with the creation of a Basket.”

Nevertheless, the truly determined and experienced can ferret out whether there is tungsten contained in their gold bars. In fact, some already have found tungsten in bars which purport to be gold and this is how.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Why Tungsten Alloy is Used as Gold Substitution?

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 11:52

In theory, as its density is 19.1g/cm3, which is approximately 70% denser than lead, uranium could be used as material of making fake coin. However, it is weakly radioactive and not as dense as gold, so it does not appear to be a practical method. Then people have discovered that tungsten is environmental-friendly, durable and hardness, the most important is that its density of 19.25g/cm3 is just about the same density as gold (19.3g/cm3), which bears the similar specific gravity. These advantages make tungsten enjoys the superiority to be the best substitute for the costly metal of gold or platinum. It is necessary to tell that alloying gold with tungsten would not work for several reasons but a coin with a tungsten center and gold all around it could not be detected as counterfeit by density measurement alone.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Boring Bar and Tungsten Bucking Bar

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 10:14

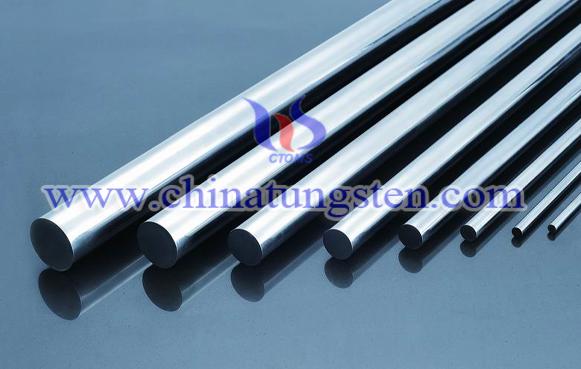

Tungsten heavy metal boring bars are manufactured in sintered or polished alloys of 90%-95% tungsten with a nickel-copper-iron-moly matrix. These alloys are very similar to tungsten-carbides but the chemical composition is developed differently to reduce embrittlement. The high density (twice as heavy as steel) and tensile strength (110 kpsi) of this alloy makes the ideal combination for chatter free tools and supper chatter free tools. Heavy metal boring bars greatly enhance boring application by absorbing vibration and drastically reduce chatter, enabling to machine deeper bores with greater precision and finish.

Tungsten heavy alloy bucking bars are denser than steel, resulting in a bucking bar of the same weight but half the size. Bucking bars are used in rivet setting to upset the shank of the rivet. Tungsten Heavy Alloy bucking bars reduce the recoil when reflecting the impact back to the rivet shank.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Bucking Bar Knowledge

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 10:08

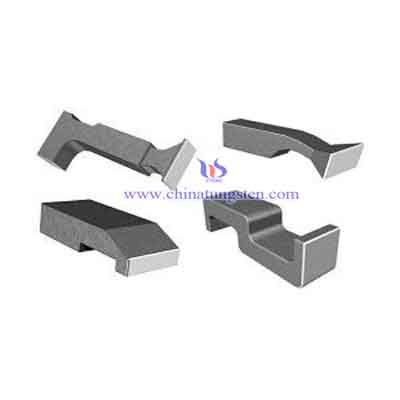

A bucking bar is used to form the shop head of a rivet. It is held against the shank of a rivet and as the rivet gun bangs on the factory head the bar 'bucks' against the shop head causing the metal to deform. That deformation mushrooms the shank forming the shop head. There are many shapes, sizes, and weights of bucking bars. Many are shaped and sized for special-purpose (generally difficult) situations. Pictured is a typical set of bucking bars.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantage of Tungsten Bucking Bars

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 09:46

The tungsten bucking bars are designed to significantly reduce vibration and provide greater comfort for the operator. These bars are up to twice as heavy as their ductile iron counterparts. Results have shown that using Tungsten bars is far superior to ductile iron and helps to reduce carpel tunnel syndrome. All edges are burr-free and all surfaces are polished to provide superb riveting results.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Properties of Silicon Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 18:04

SiC is a ceramic material with an outstanding hardness, only surpassed by diamond, cubic boron nitride and boron carbide. The material is highly wear resistant and chemically inert to all alkalies and acids. It is also highly heat resistant. These properties makes Silicon Carbide an outstanding abrasive and ceramic material to be used under extreme operating conditions.

• Density: 3.21 g/cm3

• Vickers hardness: 29 GPa

• Coefficient of Thermal expansion: 5·10-6/K

• Thermal conductivity: 50 to 100 W/m K

• Typical temperature resistance: 1500°C in air, 2400°C in inert atmosphere

• Specific heat: 750 J/kg K

Tungsten Carbide Manufacturer & Supplier: http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

HQ-9 & Tungsten Alloy Swaging Rod

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 17:52

Tungsten alloy swaging rod is made of tungsten alloy rod through calcinations. The normal method used in the processing are extruding, forging and sintering. After calcinations, tungsten alloy swaging rod has higher ductility, toughness and tensile strength than tungsten alloy rod, so it can be used for a longer time. Tungsten alloy swaging rod has been widely used by HQ-9.

The HQ-9 is China’s new generation medium- to long-range, active radar homing air defence missile.

The land-based HQ-9 system has an anti-radiation variant, known as the FT-2000 for export. The export designation for air defense version is FD-2000 (with FD stands for Fang Dun, meaning defensive shield), and its developer China National Precision Machinery Import and Export Corporation (CPMIEC) first made it public at the Africa Aerospace and Defence Exhibition held at Cape Town in March 2009. In September 2013 the HQ-9 submitted by CPMIEC won Turkey's T-LORAMIDS program to co-produce 12 long range air defense systems.

With the high hardness and high density of tungsten alloy swaging rod, HQ-9 has good antiaircraft performance. It can be also used to defense cruise missile.

Tungsten Heavy Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com