Ti-W-Si-Al Based Coated Tungsten Carbide End Mills In Cutting Hardened Steel Ⅵ

- Details

- Category: Tungsten Information

- Published on Thursday, 26 November 2015 16:06

- Written by zhihua

- Hits: 348

In last part we know that tungsten carbide end mills with (Ti,Al)N, (Ti,W)N/(Ti,W,Si)N, and (Ti,W)N/(Ti,W,Si,Al)N coating films will be tested to know the tool wear, because the exact features of new titanium/tungsten/silicon/aluminum-based coating films are still unknown for cutting hardened steel. Here in this part we explain the experimental procedures.

2. Experimental Procedures

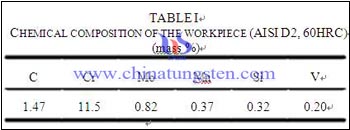

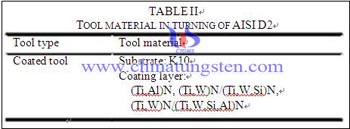

The work material used was hardened steel (AISI D2,60HRC). The chemical composition of the hardened steel is shown in Table 1. The tool material of the substrate was cemented carbide, and three types of PVD-coated cemented carbide were used as shown in Table 2. Namely, the coating films used were (Ti,W)N/(Ti,W,Si)N and (Ti,W)N/(Ti,W,Si,Al)N coating film. (Ti,W,Si,Al)N is a new type of coating film. (Ti,W)N/(Ti,W,Si)N and (Ti,W)N/(Ti,W,Si,Al)N comprise a multilayer coating system.

The inner layer of the (Ti,W)N/(Ti,W,Si)N and (Ti,W)N/(Ti,W,Si,Al)N coating system is (Ti,W)N coating film, and the outer layer is (Ti,W,Si)N and (Ti,W,Si,Al)N coating films, respectively. Furthermore, commercial (Ti,Al)N-based coating film was also used as the (Ti,Al)N.

(To be continued. This article is divided into several parts. Here is part 6. For part 5 please refer to http://news.chinatungsten.com/en/tungsten-information/80796-ti-10487)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com