Anti-Sag Tungsten Wire Performance

- Details

- Category: Tungsten Information

- Published on Friday, 27 September 2013 20:00

- Hits: 1938

Tungsten at a certain temperature and a certain resistance to their sagging under load deformation capacity. Anti-sagging properties of the material is actually a reflection of high temperature creep resistance, which is doped with tungsten is a very important performance indicators.

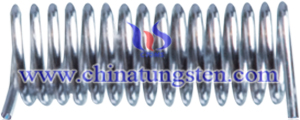

Tungsten filament incandescent bulbs and a vacuum device, its working temperature is usually above 2000 ℃, so the effect of high temperature and tungsten weight, since the material strength is decreased and the grain boundary sliding and produce sag. To ensure that the shape of the filament at a high temperature and dimensional stability, requires tungsten must have good high temperature sag resistance capability. This capability and the recrystallization temperature of tungsten grains after recrystallization geometry closely related. For doped with potassium, aluminum, silicon, tungsten wire, because of its high recrystallization temperature, and recrystallized to form a large aspect ratio of recrystallized grains, and between the grains was dovetail lap, this structure makes the most of the grain boundary is parallel or nearly parallel axes wire, which significantly improves the ability of the tungsten filament temperature sag resistance.

Tungsten-doped high-temperature sag resistance capacity, mainly by the potassium tungsten bulb size, number, and distribution (dispersion state) is determined, and the dispersion state of the bubble in addition to potassium and potassium in the outside, suitable deformation and heat treatment system is essential, the former is the ability to obtain a prerequisite for sag resistance, and the latter is a necessary condition.

Determination of anti-sag tungsten wire performance in many ways, a common high-temperature creep test method, high flexural droop method (V-shaped test) and so on. Service conditions from the point of view of the filament, sagging test method than the creep test method using tungsten better meet the actual situation. Thus creep test method is gradually being replaced by sagging test for detecting anti-sag tungsten high temperature performance.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-Rhenium Wire Problems in Useing

- Details

- Category: Tungsten Information

- Published on Friday, 27 September 2013 19:56

- Hits: 1915

1 Errors Introduced by Improper Installation

Thermocouples should be mounted too close to the door and the heated places, insertion depth should be at least the diameter of the protective tube 8 to 10 times , and the insertion depth of the installation position does not reflect the true temperature of the furnace . Thermocouple protection tube with intramural interval Unfilled adiabatic material , resulting in overflow hot or cold air furnace , so the thermocouple protection tube and the gap between the furnace wall hole applications such as refractory cement or asbestos insulating material clogging rope to avoid hot and cold air convection and affect the accuracy of temperature measurement . Thermocouple should be installed as far as possible away from strong magnetic fields and strong electric field, thermocouple and power cables should not be wire-bound with a catheter in order to avoid the introduction of interference caused by errors. Thermocouples can not be installed in measured media rarely flows in the region, when measured with a thermocouple tube gas temperature must be going against the flow direction of the thermocouple installation , and full contact with the gas .

2 Error Introduced Insulation Deterioration

Such as thermocouple protection tubes and pull plates excessive dirt or salt residue resulting thermocouple very poor insulation between the wall of the furnace at high temperature is more serious , it will not only cause the loss of thermoelectric power but also the introduction of interference , resulting the error sometimes up on Baidu .

3 the Error Introduced by the Thermal Inertia

As the thermal inertia of the thermocouple indication value of the instrument behind the measured temperature changes , while a fast measurement of this effect is particularly prominent. It should be possible using the hot electrode smaller, smaller diameter thermocouple protection tube . Temperature environment permit, or even take away the protective tube . Because of measurement hysteresis , thermocouple temperature fluctuation of the detected temperature fluctuation amplitude is small amplitude . Measuring lag larger the smaller the amplitude of fluctuation thermocouple , the greater the difference between the actual oven temperature . When a large time constant thermocouple or temperature control , the instrument displays the temperature fluctuation is small though , but the actual oven temperature fluctuations may be significant. To accurately measure the temperature , time constant should be selected thermocouple . The time constant and the heat transfer coefficient is inversely proportional to the diameter of the thermocouple hot end , and the material density is proportional to the specific heat , such as to reduce the time constant , in addition to increasing the heat transfer coefficient , the most effective way is to minimize the size of the hot end . Use, usually good thermal conductivity materials, thin wall, small diameter protection tube . In the more precise temperature measurement, the use of non- bare wire thermocouple protection tube , but the thermocouple easily damaged, should be promptly corrected and replaced.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-Rhenium Alloy Wire Using Profile and Performance

- Details

- Category: Tungsten Information

- Published on Friday, 27 September 2013 19:41

- Hits: 1929

Tungsten-based alloy elements added rhenium, tungsten alloy. The rhenium content of the alloy is typically: 1%, 3%, 5%, 20%, 25% and 26% and so on. Tungsten often bred in the grain interface microcracks, these micro-crack is caused by tungsten broken off an important reason. Tungsten-rhenium alloy is formed in the deformation twinning process easy, thus reducing the stacking fault energy of layers, reduce the grain boundary movement of dislocations impedance, resulting in increased mobility of dislocations promote tungsten solution softened. This phenomenon is called "rhenium plasticizing effect." Tungsten rhenium alloy series, the low concentration of rhenium rhenium plasticizing effect is obvious, rhenium, rhenium concentration is high plasticizing effect decreases.

Tungsten-rhenium alloy wire for tungsten rhenium thermocouples

W-3Re/W-25Re, W-5Re/W-20Re, W-5Re/W-26Re, W/W-26Re, 2: Binding for single crystal sapphire sapphire tungsten rhenium wire or tungsten rhenium alloy wire used Model: W-25Re, 0.5mm diameter

Tungsten-rhenium alloy has a series of excellent properties such as melting point, high strength, high hardness, high ductility, high recrystallization temperature, high resistivity, low vapor pressure, low electron work function, and low ductility brittle transition temperature.

Tungsten-rhenium alloy addition to the above performance, low-rhenium alloy and high-rhenium alloy wire thermocouple into the match, with a high thermoelectric power values. Various types of tungsten rhenium thermocouple thermoelectric power value and temperature relationships.

Sapphire single crystal tungsten rhenium wire binding with commonly used models: W-25Re, 0.5mm diameter.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Tungsten Rhenium Alloy Wire Production Process

- Details

- Category: Tungsten Information

- Published on Friday, 27 September 2013 19:50

- Hits: 1900

1.1 powder preparation and doping techniques

Preparation of low temperature pre-reduction of suitable phase composition of blue tungsten oxide , and tungsten blue oxide is doped tungsten powder acid , tungsten powder as needed , and control the ratio of rhenium powder .

Doping uniformity is the first element control , to be able to obtain a stable in terms of purity , scale, and the particle size requirements of the three indicators .

The use of advanced hydrogen reduction equipment, as well as doping , pickling, large capacity V-type mixed powder machine , especially for hydrogen production system optimization , for the implementation of powder technology to provide reliable protection .

1.2 sintering and molding processing technology cogging

Using isostatic round billet rolling through vertical melt after blooming , which is tungsten and molybdenum Solton most advanced processing technology , preparation of billet single weight 3 kg , the use of high-power -controlled vertical melt equipment, to stable obtain density , purity and grain size , etc. to meet the requirements of the master index tungsten rhenium billet .

Blooming accommodate large rolling method billet , to achieve quality and efficient, large-scale production of the best processing methods. Solton tungsten and molybdenum technology uses KDCKS three multi-stand rolling mill rolls and master its system technology. At present, most enterprises still use rotary forging billet made to open , but open up technology and equipment, molds, auxiliary facilities and so has shrunk, with advanced rationality.

1.3 swaging and stretching techniques

Multimode string forging more with welding, high frequency continuous annealing , Big Wheel and multimode continuous drawing machine drawing machine applications, using a large compression rate processing, oxidation annealing , using condensate crystal drawing dies , etc., composed this section technical characteristics .

Using a large compression ratio stretched to the protection of tungsten rhenium wire has good high temperature performance with excellent positive significance. Has adopted pass compression rate specification , ¢ 3.7-0.7mm range of 30% -40%, ¢ 0.7-0.2mm range of 18% -28 % . Four to ten die mold sliding multimode drawing machine has been applied .

1.4 Electrochemical Processing Technology

Since sapphire tungsten rhenium alloy wire with multi- supplier status with white silk , so it is necessary to wash separately electrolytic corrosion , galvanic corrosion and electrolytic polishing reducing effect.

1.5 Control Management Technology

Because they have a better grasp of APT and ammonium perrhenate from raw materials to final products, all tungsten rhenium wire process control and management techniques to develop more scientific focus of the process measurement and control standards, and has a full range of advanced testing methods, Solton tungsten and molybdenum Technology is focused on creating ¢ 1.0-0.2mm range crack detection system .

1.6 Equipment Technology : mixer, reduction furnace , vertical melt equipment, rotary swaging machine, wire drawing machine, electrochemical etching equipment, testing equipment and packaging machines.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-Rhenium Wire Thermocouple Temperature and The Use of Environmental

- Details

- Category: Tungsten Information

- Published on Friday, 27 September 2013 19:37

- Hits: 1826

Tungsten-rhenium wire thermocouple temperature

Its maximum temperature can reach 2800 ℃, however, higher than 2300 ℃, the data is scattered. Therefore, the use of temperature, preferably at about 2000 ℃.

The use of tungsten rhenium wire thermocouple atmosphere

Easily oxidized tungsten-rhenium thermocouples, suitable for hydrogen in an inert or dry use, or dense protective tube isolated in order to use it with oxygen. Carbon-containing atmosphere can not be used (as in the use of hydrocarbon-containing atmosphere, the temperature exceeds 1000 ℃ i.e. by corrosion). Tungsten or tungsten-rhenium in a carbonaceous atmosphere is easy to form a stable carbide, that reduce the sensitivity and cause brittle fracture, in the case of the presence of hydrogen, is accelerated carbonation.

5, tungsten-rhenium thermocouples antioxidant. The issue has been a subject of concern to scholars at home and abroad, and is committed to study and solve. Our company adopts the international advanced making process, successfully developed a high temperature and pressure fabricated W-Re thermocouple, the temperature of the product range is 0 ~ 1800 ℃, widely used in metallurgy, coking, chemical furnace, heat treatment, glass and other industries, it has a high accuracy, low price, stable performance, the work atmosphere free from restrictions, etc., instead of platinum and rhodium thermocouple is the ideal product. I produced the W-Re thermocouple in Zhuzhou Cemented Carbide Works, Zigong Cemented Carbide factory and Shenyang Branch of the instrument, such as units, widely used, the performance reached the level of similar foreign products.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com