WO3 Enhances SCR Denitration Catalyst Activity and Thermal Stability

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 March 2016 19:53

- Written by chunyan

- Hits: 252

Tungsten trioxide can be used in lots of fields, the mainly use is calcined to produce tungsten and tungsten carbide powder, then to produce carbide products, such as cemented carbide cutting tools; at the same time, the tungsten trioxide is also very good shielding material, and using in X-ray shielding and fireproof fabric frequently; in addition, another important use of tungsten trioxide is used as raw material for producing SCR denitration catalyst.

Catalyst is the core part of the SCR technology; its effective operation determines SCR denitration system efficiency and economy. The mainly active substances of SCR method denitration catalyst are titanium dioxide, vanadium pentoxide, tungsten trioxide, molybdenum trioxide, etc., among them titanium dioxide is the effective carrier. Vanadium oxide can disperse uniformly on the titanium dioxide surface, and anatase titanium dioxide is the highest activity in industry. Vanadium pentoxide being the most important active ingredient in SCR denitration catalyst, the amount of it is different in different catalysts, but the higher vanadium pentoxide content leads to a higher activity of the catalyst.

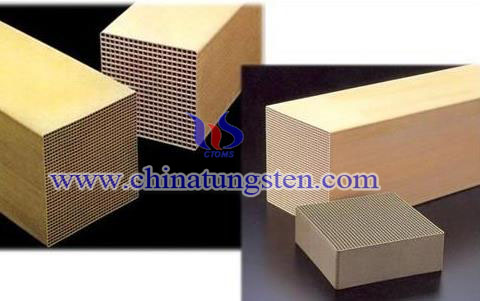

However, due to the extremely high activity of vanadium pentoxide, it will oxidize sulfur dioxide into sulfur trioxide, which will affect SCR denitration catalyst efficiency. Therefore, a high level of vanadium pentoxide is generally not recommended, the many using of denitration catalyst contents 2%~5% of vanadium pentoxide. The introduction of tungsten trioxide plays a major role in enhancing the activity and increasing the thermal stability of the denitration catalyst. That is because tungsten trioxide can limit catalyst being sulfated, the SCR denitration catalyst commonly used containing 5%~10% of tungsten oxide. Molybdenum trioxide takes the main role of improving catalyst activity and preventing catalyst being poisoned by As in the flue gas. But because molybdenum trioxide disadvantages to catalyst forming, and reducing the ratio of honeycomb catalyst end product, so molybdenum trioxide is mainly used in producing flat-catalyst.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com