Pressure Influencing Tungsten Trioxide Ceramic Density

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 February 2016 16:48

- Written by qiongyao

- Hits: 249

Pressure refers to the object of force occurs in two contact surfaces, or gas to the vertical forces of solid and liquid surface, liquid or solid surface of the vertical force. Solid surface pressure is usually the result of elastic deformation; it is generally the contact force. The surface of the liquid and the gas pressure is usually the result of gravity and molecular motion. The observed effects of stress are not perpendicular to the direction of the contact surface, which usually is a result of pressure and friction interaction.

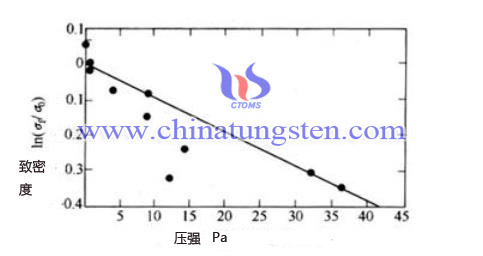

Detection molding pressure affects densification of tungsten trioxide, preparing the pressure is 4MPa, the sintering temperature is 1200 ℃, holding time 2h to analyze.

The test results in the following table:

|

Pressure(MPa) |

Density(g/cm³) |

Shrinkage(%) |

|

3 |

6.67 |

9.87 |

|

4 |

6.73 |

11.2 |

|

5 |

6.75 |

11.2 |

|

10 |

6.80 |

10.5 |

As it can be seen from the data in the table above, we can see sintering densification increases with pressure increasing. In general, the greater the pressure molding, the particles contact more closely, the diffusion resistance is smaller, but the high pressure molding powder may cause brittle fracture. Visible, in order to obtain high-quality tungsten trioxide ceramics, the pressure should be controlled between 4MPa and 5MPa, so that the grain linked closely together.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com