Inquiring Tungsten Trioxide Ceramic Sintering Phase

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 February 2016 16:43

- Written by qiongyao

- Hits: 228

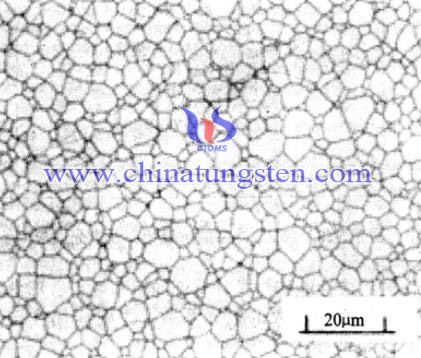

The study shows that the tungsten trioxide ceramics we prepared sintering at 1180 ℃, the relative density can reach about 94%. This means that the solid-phase sintering of both the early and mid-stage of our design before sintering process conducted post-sintering generally begins with relative density of the sintered body is greater than 90% at this stage, which is mainly a small pore exclusion and isolation grain growth. Pore radius of curvature by stress shrinking, with the closed pores increase in the gas pressure to achieve balance. Closed pores of the grain boundary portion fill the internal volume of the crystal through diffusion, this process is slow, and the densification is restricted. Late sintering, pores become isolated and grain boundaries communicate with each other form network, so it is only through the discharge pore volume of the grain boundary diffusion or to achieve grain growth through grain boundary migration.

The study shows that the tungsten trioxide ceramics we prepared sintering at 1180 ℃, the relative density can reach about 94%. This means that the solid-phase sintering of both the early and mid-stage of our design before sintering process conducted post-sintering generally begins with relative density of the sintered body is greater than 90% at this stage, which is mainly a small pore exclusion and isolation grain growth. Pore radius of curvature by stress shrinking, with the closed pores increase in the gas pressure to achieve balance. Closed pores of the grain boundary portion fill the internal volume of the crystal through diffusion, this process is slow, and the densification is restricted. Late sintering, pores become isolated and grain boundaries communicate with each other form network, so it is only through the discharge pore volume of the grain boundary diffusion or to achieve grain growth through grain boundary migration.

The sintering is divided into three stages:

1: The initial stage of sintering. Embryo between powder particles in contact with each other through the mass transfer process, called sintering neck, and through their growth so that the embryo shrinkage;

2: Sintering the medium term. Grain growth begins at the beginning, and it is accompanied by a wide range of facets formed between the particles. In this case, the pores remain interconnected into continuous network, and the crystal interfaces between the particles remain isolated from one another. Most of the densification process and partially microstructure are produced in this phase;

3: Post-sintering. With the sintering process porosity becomes isolated, isolated pores eliminates the grain boundaries began at the grain boundary diffusion to form a continuous network. Post-sintering densification rate slowed down, and the development of microstructure such as grain growth is more rapid.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com