Sodium Tungstate Addition on Nickel-Tungsten-Phosphorus Alloy Coating Influence

- Details

- Category: Tungsten Information

- Published on Friday, 15 January 2016 18:49

- Written by linlu

- Hits: 280

Alloy, is the material with metallic properties, which is made up of two or more metal or nonmetal. Generally it’s obtained by fusion into homogeneous liquid and solidification. According to the number of elements, it can be divided into binary alloy, ternary alloy and multicomponent alloy. So the ternary alloy is the alloy containing three elements.

To prolong the life of continuous casting crystallizer, domestic scholars added sodium tungstate in electroplating nickel-phosphorus alloy liquid to prepare nickel-tungsten-phosphorus ternary alloy. They also studied the influence of sodium tungstate content in plating solution on the alloy coating hardness, abrasion resistance and adhesion. At the same time, they compared the ternary alloy and properties of base material.

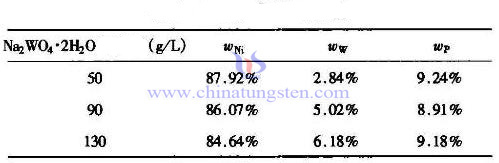

1. The content of composition in the coating:

According to the difference of adding amount of sodium tungstate, nickel-tungsten-phosphorus alloy coating obtaining different W content can be obtained. The component content in alloy plating is as shown in the figure. Known from the figure, in the test conditions, with the increase of the content of sodium tungstate, the content of tungsten in coating also increases. When the addition of sodium tungstate is 90 g/L in the plating solution, the tungsten content increases more quickly in the coating.

2. The coating and the substrate binding force:

When tungsten content in the coating is different, the binding force of the coating and substrate is also different. According to this experiment, when the content of tungsten is 5.02%, the binding force of the coating and substrate is best. When tungsten content is 2.84%, the coating is worst.

3. The cross section morphology of coating

Through watching photos, we can find that the substrate and alloy plating organizations are fibrous, but alloy coating crystallization is thin than substrate.

4. The hardness and wear resistance of coating and the substrate:

Compared with the substrate materials, the hardness and wear resistance of three kinds of alloy coatings obviously increase. And with the increase of the tungsten content in the coating, the hardness gradually improves and wear resistance increases.

To sum up, using the plating nickel-tungsten-phosphorus alloy layer technology to extend the life of crystallizer is technically feasible, and the content of sodium tungstate in plating solution will affect the performance of the coating. Under this experimental condition, the suitable addition amount of sodium tungstate is 90g/L. In actual production, the damage of crystallizer Cu material is very big. Only selecting the appropriate composition of plating solution and process conditions and plating a layer of alloy coating on the substrate, the surface properties will be improved and the life of the crystallizer will be extended.

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com