Ammonium Paratungstate Mechanochemical Decomposition

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 15:00

- Written by Cristina

- Hits: 326

The possibility of mechanochemical decomposition of ammonium paratungstate (APT) has been studied, and compared with thermal decomposition method. For this purpose, APT powders were milled using a planetary ball mill up to 36 h and under air atmosphere. For thermal decomposition, APT powders were heated for 30 minutes at 300 and 450 °C in air atmosphere.

X-ray diffraction (XRD), differential scanning calorimeter (DSC), and thermo gravimetric analyzer (TGA) were used to study the decomposition progress, and products. The XRD results showed that APT completely decomposed to WO3 by thermal decomposition, while the final product of mechanochemical decomposition was WO3 (H2O)0.5. According to DSC and TGA results, during thermal decomposition, ammonia and water released in four steps, and leaved WO3. By mechanochemical decomposition crystal water and ammonia liberated from APT structure, but structural water of APT remained. In both methods, an X-ray amorphous phase was the intermediate product of APT decomposition.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cobalt Doped Ammonium Paratungstate Reduction

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 14:58

- Written by Cristina

- Hits: 341

Cobalt doped ammonium paratungstate (Co-doped APT) precursors for the fabrication of cemented carbides were synthesized by co-precipitation, where W and Co are mixed on the atomic scale. The effect of cobalt content on the reduction of W–Co precursor was studied. W–Co precursors with different ratios of tungsten to cobalt were prepared and calcined at 220 °C for 5 h in air, followed by a reduction in hydrogen gas at 600 and 650 °C for different times. The resulting powders were characterized with respect to phase constituent, specific surface area, particle size, density, and morphology of the reduced powders.

It has been found that the addition of cobalt results in a higher reduction rate toward the metallic phases. However, the particle size of the reduced powders increases with increasing cobalt content, while its relative density decreases. The specific surface area of reduced powders at 650 °C increases for short reduction times, due to reduction of oxides to metal powder, and decreases for long reduction time due to agglomeration of metal powder. Cobalt plays the role as a catalyst during the reduction processing. On the other hand, it promotes the agglomeration of small particles. However, the completely reduced powders were well nanostructured with an average particle size between 20–50 nm.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Decomposition Thermoanalytic Study

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 14:48

- Written by Cristina

- Hits: 369

Non-isothermal kinetic (k, A and ΔE) and thermodynamic (ΔH, Cp and ΔS) parameters of ammonium paratungstate decomposition to the onset of formation of WO3, were determined by analysing thermogravimetry (TG), differential thermal analysis (DTA) and differential scanning calorimetry (DSC) curves recorded at various heating rates (1–30°C min−1). Thermal events encountered throughout the decomposition course were due to three endothermic (at 120 ° C (I), 195 ° C (II) and 359 ° C (IV)) and two exothermic (at 265 ° C (III) and 386 °C (V)) processes. The events I–IV were accompanied by weight losses resulting from the elimination of volatile components [(NH4)2O, NH3 and H2O] leading to the formation of intermediate solid products (metatungstate and polytungstate), whereas event V was due to the crystallization of WO3 in the immediate vicinity of its formation (at 370 ° C).

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Concentrate Preparing Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 14:54

- Written by Cristina

- Hits: 367

In order to improve the quality of tungsten products and the export need of tungsten wire, the method for producing high purity ammonium paratungstate is under research. In order to reduce producing cost, improve producing efficiency of tungsten, ammonium paratungstate prepared by tungsten concentrate is studied.

Tungsten concentrate preparing ammonium paratungstate mainly uses soda lye under alkaline leaching tungsten concentrate. During the processing procedure, the alkaline using amount is 2-3.5 times more than the theoretically amount. The first step is evaporation and crystalline of sodium tungstate. Firstly evaporate sodium tungstate in the reaction tower, coarse sodium tungstate crystal is produced. Then add water and hydrochloric acid into it and then acid decomposition happens. After acid decomposition, tungstic acid is produced and was mixed up with ammonium. It is then being processed under 80-95 degree Celsius for 4-6 hours, evaporation amount is between 60-70. The final process is crystalline, filtering, washing and dry. Then the finished ammonium paratungstate is made.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

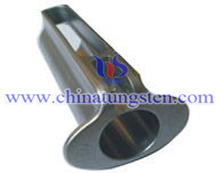

Tungsten Syringe Shield

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 12:59

- Written by wenjing

- Hits: 394

Due to tungsten alloy has high density, excellent radiation attenuation properties, and environmetal frendly, it is widely used to produce into tungsten syringe shield. Tungsten syringe shields, also called injection shields, are designed to reduce hand exposure to radioactive injections. With a great ability of radiation shielding, the barrel of the tungsten syringe shield can reach 0.06''-0.08''. And it is able to reduce radiation exposure from Tc-99m by more than 99%.

Detials of Tungsten Syringe Shield:

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com