Superiority of Tungsten Carbide Dies

- Details

- Category: Tungsten Information

- Published on Thursday, 12 July 2018 16:58

- Written by meilan

- Hits: 630

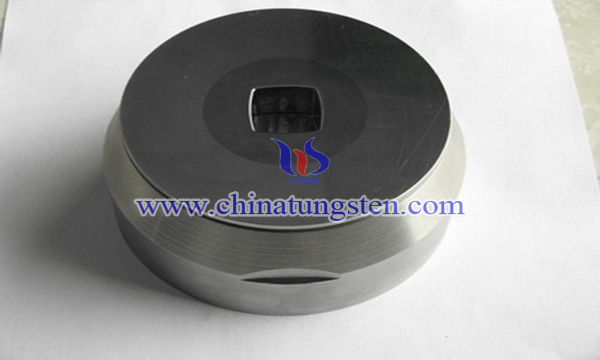

Grinding of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Thursday, 12 July 2018 16:55

- Written by meilan

- Hits: 580

Brief Introduction of The Tungsten Carbide Drawing Die (1)

- Details

- Category: Tungsten Information

- Published on Thursday, 12 July 2018 16:49

- Written by meilan

- Hits: 599

Read more: Brief Introduction of The Tungsten Carbide Drawing Die (1)

Brief Introduction of The Tungsten Carbide Drawing Die (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 12 July 2018 16:52

- Written by meilan

- Hits: 629

Read more: Brief Introduction of The Tungsten Carbide Drawing Die (2)

Microporous Ceramics for Tungsten Smelting

- Details

- Category: Tungsten Information

- Published on Monday, 09 July 2018 23:06

- Written by meiwei

- Hits: 610

Microporous ceramics are a kind of silicate products. The raw materials used are barren clay, waste slag, power plant fly ash and glass plant waste, which will play an important role in protecting the environment and saving resources. Microporous ceramic is a functional structural ceramics. Microporous ceramics, such as adsorbability, permeability, corrosion resistance, environmental compatibility and biocompatibility, are widely used in the filtration of various liquids, filtration of gases, and immobilization of biological enzyme carriers and biocompatibility carriers, especially in environmental engineering, such as industrial water and domestic water treatment, The purification of sewage and so on.

sales@chinatungsten.com

sales@chinatungsten.com