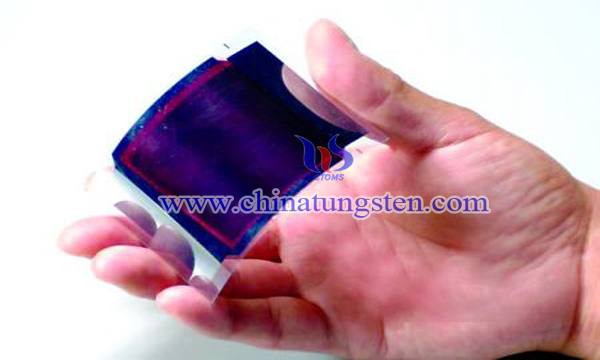

Tungsen Trioxide Electrochromic Nanofilm

- Details

- Category: Tungsten Information

- Published on Monday, 23 July 2018 18:43

- Written by yuntao

- Hits: 2194

Electrochromism refers to the phenomenon that displayed by some materials of reversibly changing color under the action of an applied electric field. Electrochromic device only needs a small voltage (about 2V) to work, and the original color or fading state can be maintained in the open circuit, so the energy consumption is less.

New Manufacture Process for Tungsten-Oxide Ethanol Sensor

- Details

- Category: Tungsten Information

- Published on Monday, 23 July 2018 18:37

- Written by yuntao

- Hits: 432

The ethanol gas sensor can detect the ethanol content in drunk driving inspection or industrial production, So as to reduce or avoid traffic accidents or production safety accidents. In recent years, the development of ethanol sensors has become more extensive and in-depth, and the ethanol sensing characteristics of tungsten oxide have received extensive attention from researchers.

Read more: New Manufacture Process for Tungsten-Oxide Ethanol Sensor

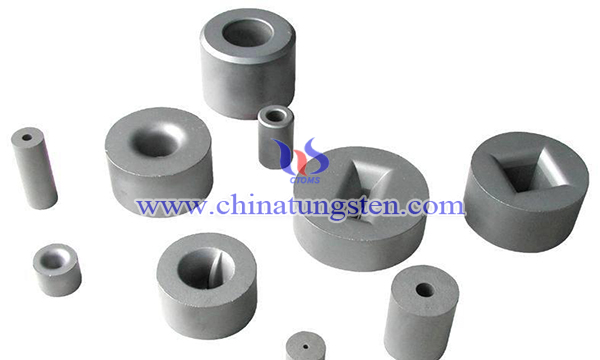

Market Analysis of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:30

- Written by meilan

- Hits: 514

Short Run Production of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:33

- Written by meilan

- Hits: 536

Design and Manufacture of Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Sunday, 22 July 2018 20:27

- Written by meilan

- Hits: 502

sales@chinatungsten.com

sales@chinatungsten.com