How to Produce Tungsten Titanium Powder with Quality and Quantity Guarantee

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 22:47

- Written by meiwei

- Hits: 437

In the sintering process of tungsten-titanium target, the importance of production of tungsten and titanium powder is obvious. The properties of tungsten titanium powder greatly affect the properties of tungsten-titanium products. With the increasing demand of the market, the production of tungsten titanium powder has not only the requirements of chemical purity, but also the requirements of physical and technological properties. In particular, the preparation technology of ultra-fine tungsten titanium powder for some special purposes needs to be solved.

Read more: How to Produce Tungsten Titanium Powder with Quality and Quantity Guarantee

Weight Reduction Plan for Cerium Tungsten Alloy Wire

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:43

- Written by meiwei

- Hits: 464

Compared with traditional thorium tungsten alloy wire, cerium tungsten alloy wire has lower electron escape work (only 2.8eV, 10% lower than thorium-tungsten alloy wires), higher emissivity (27 times higher than thorium-tungsten alloy wires at 1500K), higher luminescence efficiency (10-15% higher than thorium-tungsten alloy wires), lower arcing voltage (about 40% higher than thorium-tungsten alloy wires), and no human body. The radioactive pollution produced by the body is a good product of green environmental protection. It can be used to replace thorium tungsten alloy wires in electron emission tubes, argon arc welding, etc. It has very broad application prospects in high-demand electric light sources.

Read more: Weight Reduction Plan for Cerium Tungsten Alloy Wire

Tungsten Containing Mesoporous Materials Preparation Process

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:10

- Written by meiwei

- Hits: 414

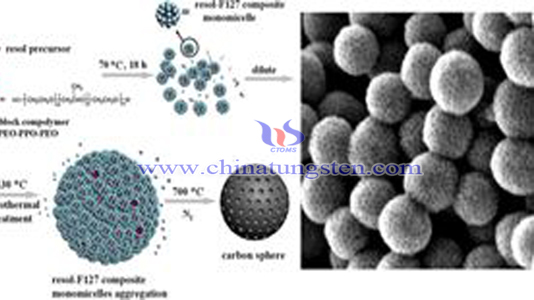

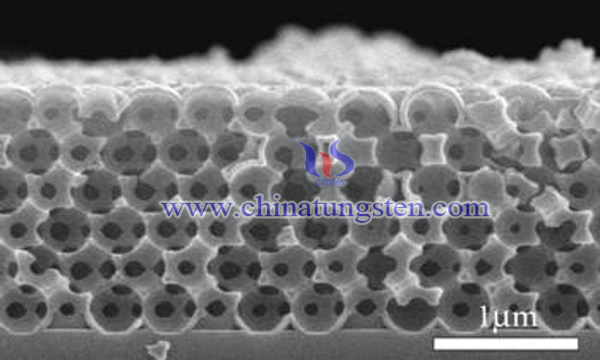

Tungsten containing mesoporous materials have nano-scale homogeneous pore structure and huge surface area. They are a good catalyst carrier. By introducing active components into mesoporous materials, they can provide the active sites needed for catalytic reaction. They have shape-selective catalytic properties and are typical micro-reactor.

Read more: Tungsten Containing Mesoporous Materials Preparation Process

Tungsten Oxide / Vanadium Oxide Heterojunction Nanowire Array Gas Sensing Materials

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:17

- Written by meiwei

- Hits: 411

In the 21st century, the level of industrialization has developed rapidly, but the natural environment and ecology on which human beings depend for it have been severely damaged. There are a lot of toxic and harmful gases, smog, acid rain, PM2.5, etc. in the air. Investigating NOx-based toxic gases, the market demands sensors that efficiently and accurately detect and prevent toxic and harmful gases.

Read more: Tungsten Oxide / Vanadium Oxide Heterojunction Nanowire Array Gas Sensing Materials

Tungsten Nitride-based Ternary Nanocomposite Superhard Film Material

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 19:40

- Written by meiwei

- Hits: 483

With the development of society, the requirement for materials is higher and higher. In some application fields, materials are required not only to have flexibility and strength, but also to have certain hardness and wear resistance, such as cutting tools in mechanical processing, drills for deep energy exploration, dies used in mechanical manufacturing and cylinder block of engine, etc.. For this reason, people try to use surface modification technology and surface coating technology to not only maintain the high strength and toughness of the material matrix, but also give play to the advantages of super-hard, super-strong and wear-resistant surface coating, thus greatly improving the durability and adaptability of the material.

Read more: Tungsten Nitride-based Ternary Nanocomposite Superhard Film Material

sales@chinatungsten.com

sales@chinatungsten.com