Chemical Vapor Synthesis (CVS) of Tungsten Nanopowder in Thermal Plasma Reactor Using Ammonium Partungstate

- Details

- Category: Tungsten Information

- Published on Friday, 13 November 2020 02:29

- Written by yuntao

- Hits: 1796

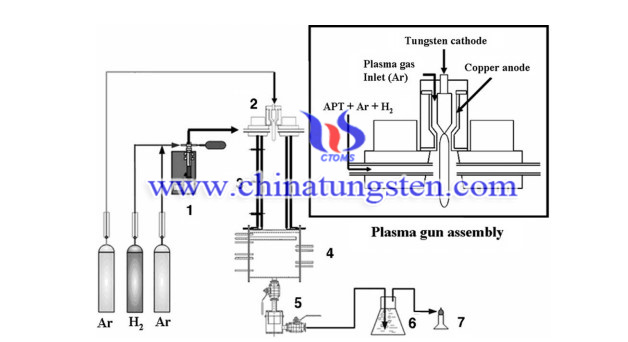

The main sources of tungsten are the high-grade concentrates of wolframite and scheelite ores. Tungsten metal powder is produced from these minerals typically through the intermediate product of ammonium paratungstate (APT). In a subsequent process, tungsten oxides are obtained from APT by calcination in an oxygen bearing atmosphere between 560 °C and 850 °C. Tungsten metal powder is then produced by reducing the oxides with H2. However, it is difficult to produce nanosized tungsten powder with conventional evaporation and condensation methods, due to the high temperature that is needed for evaporation. Nanosized tungsten powder can be produced by various methods such as the electrodeposition, sputtering, ball milling, and complicated chemical methods. But these methods involve multi-steps and have difficulty in establishing commercial application.

A Large-Scale Production of Tungsten Trioxide Nanoparticles Using Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 13 November 2020 02:10

- Written by yuntao

- Hits: 1729

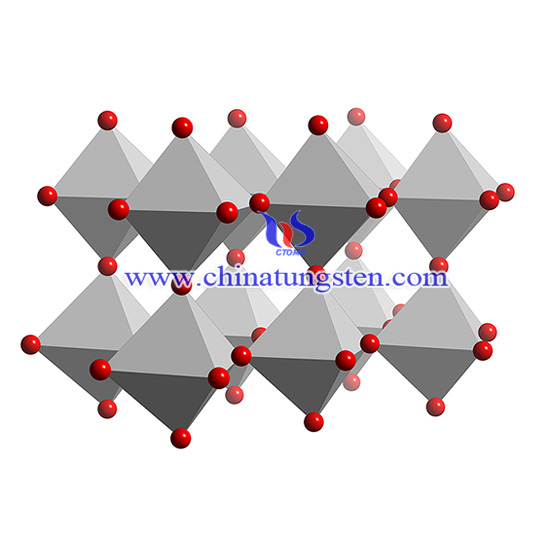

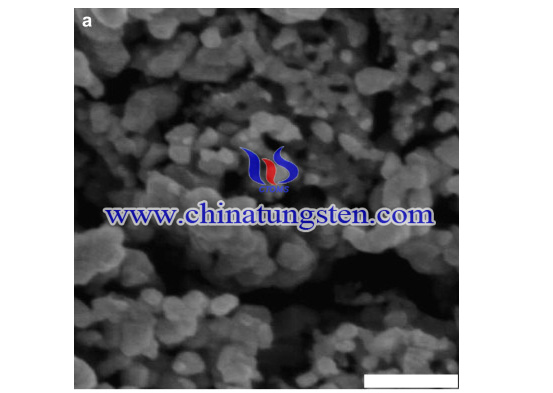

Tungsten trioxide (WO3) powder has been applied in production of light filaments and tungsten carbide. As more of its characteristics have been discovered, WO3 powder has expanded its applications in devices such as electrochromic display, semiconductor gas sensors and photocatalysts due to its outstanding electrochromic, gaschromic, thermochromic and optochromic properties. A WO3 powder with nanostructure is considered to possess enhanced properties mentioned above, owing to their large surface area and unique physical properties.

Read more: A Large-Scale Production of Tungsten Trioxide Nanoparticles Using Ammonium Paratungstate

Ammonium Paratungstate Applied in Nanostructured Molybdenum Carbide and Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Friday, 13 November 2020 01:48

- Written by yuntao

- Hits: 1735

Molybdenum carbide (Mo2C) and tungsten carbide (WC) have attracted attention for nearly four decades, due to their noble metal-like behavior in heterogeneous catalysis. These materials are catalytically active in reactions such as hydrocarbon hydrogenolysis and isomerization, ammonia synthesis, methanation, methane reforming and water–gas shift. Existing strategies for preparing high surface area carbides frequently produce non-stoichiometric surfaces, containing either residual oxygen or excess carbon which can block the active surface. Thus, an effective method that can remove the surface carbon is necessary.

Read more: Ammonium Paratungstate Applied in Nanostructured Molybdenum Carbide and Tungsten Carbide

Ammonium Paratungstate as Doping Source to Produce VO2 Controllable Phase Transition Powder

- Details

- Category: Tungsten Information

- Published on Friday, 13 November 2020 01:58

- Written by yuntao

- Hits: 1643

Vanadium oxides include V2O3, V3O5, V4O7, V5O9, V6O13, VO2 and V2O5, in which the atom ratio of oxygen to vanadium varies from 1.5 to 2.5. Among them, VO2 presents a reversible first-order metal-insulator transition (MIT) at a critical temperature (Tc). Intensive investigations have been made on the preparation of VO2 and its properties. It is generally believed that VO2 is a monoclinic structure (M), and presents semiconductive and relatively infrared transparent below Tc, whereas it transforms into tetragonal structure (R), and presents metallic and infrared reflection above Tc. These features make the VO2 suitable for the applications in intelligent energy windows coating, optical switching devices, optical data storage medium, electrodes for electrochromics, lithium batteries and supercapacitors, etc. Nevertheless, the high critical transition temperature of VO2 material (about 68 °C) limits its application.

Tungsten Heater and Bottle Lid

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 November 2020 14:13

- Written by pure-tungsten

- Hits: 1892

Tungsten heater is used in vacuum coating furnace, which is widely used to coat the surface of bottle lid. With the development of bottles and lids, beauty is not the only target now, fashion, anti-artificial, different are all the targets with the times going.

sales@chinatungsten.com

sales@chinatungsten.com