Tungsten Trioxide Introduction 3/3

- Details

- Category: Tungsten Information

- Published on Monday, 28 December 2015 16:19

Tungsten Trioxide - Preparation

Tungsten concentrate with sodium hydroxide or soda from the melt temperature, or high pressure sodium tungstate solution prepared boiled, and then purified by ion exchange or extraction, evaporation process to obtain ammonium paratungstate crystals, and then calcined at 700 ℃ to obtain tungsten trioxide. If you are scheelite concentrate as raw material, can also be decomposed into hydrochloric acid ,, then by ammonia dissolution, evaporation process to obtain ammonium paratungstate crystals were then calcined at 700 ℃ was prepared by the tungsten trioxide. It can also be directly obtained by calcining tungstate tungsten trioxide. The main reaction is as follows:

FeWO4 + 4NaOH → 2Na2WO4 + Fe (OH) 2

MnWO4 + 4NaOH → 2Na2WO4 + Mn (OH) 2

CaWO4 + 2HCI = H2WO4 + CaCI2

H2WO4 + 2NH4 (OH) = (NH4) 2WO4 + 2H2O

12Na2WO4 + 14HCl → 5Na2O • 12WO3 + 14NaCl + 7H2O

5Na2O • 12WO3 + 10NH4Cl → 5 (NH4) 2O • 12WO3 + 10NaCl

5 (NH4) 2 • 12WO3 + 10HCl + 7H2O → 12H2WO4 + 10NH4Cl

H2WO4 → WO3 + H2O

5 (NH4) 2O-12WO3-6H2O → 12WO3 + 10NH3 ↑ + 11H2O

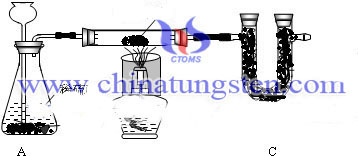

Tungsten Trioxide - Inspection

Weigh 0.5g sample, accurate to 0.000 2g, placed in 250mL beaker high type ammonia solution 40mL, cover the surface of the dish and heated in the furnace temperature, the solution was kept close to boiling point, stirring while heating the sample to complete dissolved, remove the hydrochloric acid was added 10mL After cooling to room temperature, carefully placed on a boiling water bath boiling concentrated by evaporation to a volume of about 10mL. The solution was diluted with 70 ℃ warm water to 70mL ~ 80mL, stirring constantly adding hydrochloric acid cinchonine solution 10mL, placed in a water bath (70 ℃ ± 5 ℃) on the insulation 1h, stirring once every 20min, the solution was filtered by pouring method (using Slow 11cm quantitative filter paper), glass and precipitated with beaker wall attached to a quantitative filter paper slowly wipe precipitate was washed with hydrochloric acid cinchonine lotion several times, volume control and the filtrate and washings about 180mL. The precipitate and filter paper moved to a constant weight of platinum crucible in an electric furnace carefully placed after ashing temperature furnace (750 ℃) in burning 10min, removed, cooled to room temperature was added 3mL ~ 5mL hydrofluoric acid and a few drops sulfuric acid, in a boiling water bath after nearly dry steam to move to the electric heating, the risk to make white smoke, then placed in a high temperature furnace (750 ℃) in burning 30min, removed, placed in a desiccator to cool to room temperature, weighed, repeated several times until a constant weight.

NOTE: The sample was dissolved with ammonia, the solution should be avoided so violent boiling, reduce volatilization of ammonia. If long after dissolving solution always appears cloudy or residue, quantitative filter paper, then with warm ammonia [1.5% (m / m)] repeatedly washed thoroughly beaker and filter paper, collect the filtrate and washings continue remaining experiment.

Expression of Results

Tungsten trioxide content expressed as a percentage by mass, according to equation (1):

X(%)=(m1-m2)÷m0

Wherein: X- mass percentage of tungsten trioxide, %;

m0- crucible, g;

m1- crucible and precipitation, g;

m2 Quality sample, g;

The average of the two measurements, the results reservations two decimal places;

The precision r = 0.25%; R = 0.42%.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com